|

|

| TZC petrochemical process centrifugal pump |

Selection of color |

||||||

|

||||||

| MEANING | TZC50-32-160 |

| T | Code of enterprise |

| ZC | Chemical process pump |

| 50 | The inlet dia is 50mm |

| 32 | The outlet dia is 32mm |

| 160 | Impeller dia is 160mm |

一、Product Introduction:

FEATURES:

1、TZC prtrochemical process centrifugal pump is designed and manufactured according to standard of API 610.

2、The flowing-passed components like pump body, inner rotor, pump cover, impeller, distance sleeve, etc, are all made of superior stainless steel or special materials.Accurate size and smooth runner ensure anti-corrosion and pressure resistance of pump.

3、Hydraulic components is designed and precision casted per CFD computer fluid mechanics and module design, with features of wide and smooth runner, high efficiency, good NPSH performance, small axial force, accurate size and good interchangeability.

4.Pump cover with water cooling chamber design, eliminating adverse effects of high temperature of transmission medium on the mechanical seal and bearing.

5.Three options of mechanical seal: single surface, double surface and metal bellow structure.

6. The unique automatic axial force balance system, which makes the axial force is almost zero, produce only very minor mechanical friction during long-term running and operation.

7. Increasing amount of oil in oil storage room reduces the running temperature of bearing and improve the service life of bearing.

8.Two types of coupling, diaphragm coupling and elastic pin coupling, has feature of high transmission efficency and high carrying capacity.

9.Full sealing shaft through the impeller, shaft sleeve and sealing pad and O-ring seal, ensure the axis with the media contact and improve the life of the shaft.

10.The design pressure of this pump is 2.5 MPA.

Application:

Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range: design pressure: 2.5MPA, flow: 13-2000M3/H, head: 214-160M, power: 1.1-1600KW

Applicable temperature:-80℃~+140℃(ordinary type)+140℃~+300℃(the type with water cooling chamber)

The optional accessories:monitoring of temperature device, monitoring of leakage device, preventive idling running device.

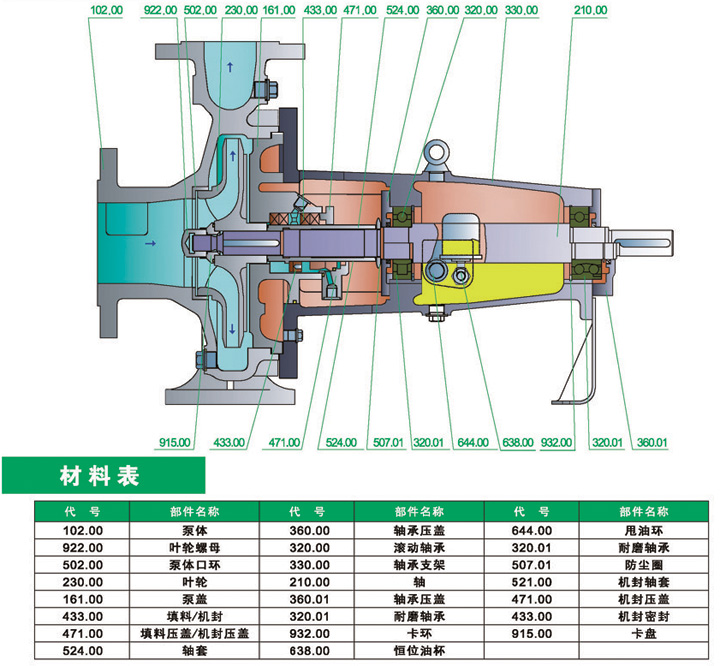

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 102 | pump body | 330 | bearing bracket | 320 | rolling bearing |

| 922 | impeller nut | 433 | seal | 921 | round nut |

| 512 | choma of pump body | 471 | gland | 211 | pump shaft |

| 230.01 | choma of impeller nut | 524 | shaft sleeve | 183 | stand bar |

| 230 | impeller | 507.01 | dust-free plate | 644 | oil slinger |

| 161.01 | choma of impeller cover | 360 | bearing gland | 638.01 | oil window |

| 230.02 | impeller choma | 922.01 | lifting ring | 915 | snap ring |

| 161 | pump cover | 672 | oil and gas separator | 320.01 | rolling bearing |

| 400.01 | gasket | 638 | oil cup |

三、Performance data sheet:

| Type | Impeller type |

Flow | Head | Efficiency | Bearing frame | NPSH | Speed | proportion=1.00 | proportion=1.35 | proportion=1.84 |

| Q | H | η | LK | n | Type | |||||

| m3/h | m | % | m | r/min | kw | kw | kw | |||

| TZC25-200 | A | 11.5 | 49 | 42 | 0 | 1.5 | 2900 | 5.5 | 7.5 | 11 |

| 5.8 | 12 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.5 | |||

| B | 10.5 | 42 | 42 | 1.5 | 2900 | 4 | 5.5 | 7.5 | ||

| 5.4 | 11 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| C | 9 | 36 | 42 | 1.5 | 2900 | 3 | 4 | 5.5 | ||

| 4.6 | 8.5 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| D | 7.5 | 28 | 42 | 1.5 | 2900 | 2.2 | 3 | 4 | ||

| 4 | 6.5 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| E | 5.5 | 16 | 42 | 1.5 | 2900 | 1.5 | 1.5 | 2.2 | ||

| 3 | 4 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| TZC25-250 | A | 10.5 | 80 | 28 | 2 | 1.2 | 2900 | 11 | 15 | 18.5 |

| 7.5 | 18 | 23 | 1 | 1 | 1450 | 2.2 | 3 | 4 | ||

| B | 9.7 | 68 | 28 | 2 | 1.2 | 2900 | 7.5 | 11 | 15 | |

| 7 | 16 | 23 | 1 | 1 | 1450 | 2.2 | 3 | 4 | ||

| C | 9 | 50 | 28 | 2 | 1.2 | 2900 | 5.5 | 11 | 15 | |

| 6.5 | 11.5 | 23 | 1 | 1 | 1450 | 2.2 | 2.2 | 3 | ||

| D | 8.5 | 30 | 28 | 2 | 1.2 | 2900 | 5.5 | 11 | 15 | |

| 6 | 6.5 | 23 | 1 | 1 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZC25-315 | A | 18.5 | 130 | 28 | 2 | 1.2 | 2900 | 30 | 45 | 55 |

| 9.5 | 32 | 25 | 0.7 | 1450 | 5.5 | 7.5 | 11 | |||

| B | 17.5 | 115 | 28 | 1.2 | 2900 | 30 | 37 | 45 | ||

| 8.7 | 29 | 25 | 0.7 | 1450 | 4 | 5.5 | 7.5 | |||

| C | 16 | 100 | 28 | 1.2 | 2900 | 22 | 30 | 45 | ||

| 7.5 | 25 | 25 | 0.7 | 1450 | 3 | 4 | 5.5 | |||

| D | 14 | 90 | 28 | 1.2 | 2900 | 18.5 | 30 | 37 | ||

| 7 | 22 | 25 | 0.7 | 1450 | 3 | 4 | 5.5 | |||

| E | 13 | 80 | 28 | 1.2 | 2900 | 18.5 | 22 | 30 | ||

| 6.8 | 20 | 25 | 0.7 | 1450 | 3 | 4 | 5.5 | |||

| F | 11.5 | 67 | 28 | 1.2 | 2900 | 15 | 18.5 | 30 | ||

| 6 | 16 | 25 | 0.7 | 1450 | 2.2 | 3 | 4 | |||

| TZC40-160 | A | 28 | 33 | 62 | 2 | 3 | 2900 | 5.5 | 7.5 | 11 |

| 14 | 8 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| B | 25.6 | 29 | 62 | 2 | 3 | 2900 | 5.5 | 7.5 | 11 | |

| 13 | 7 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| C | 22 | 22 | 62 | 2 | 3 | 2900 | 4 | 5.5 | 5.5 | |

| 11 | 5.5 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| D | 20 | 16 | 62 | 2 | 3 | 2900 | 2.2 | 3 | 4 | |

| 9.5 | 4.5 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| TZC40-200 | A | 29 | 53 | 58 | 1 | 2.2 | 2900 | 11 | 15 | 18.5 |

| 14.5 | 13 | 55 | 1 | 0.8 | 1450 | 1.5 | 2.2 | 3 | ||

| B | 26 | 47 | 58 | 1 | 2.2 | 2900 | 7.5 | 11 | 15 | |

| 13 | 11.5 | 55 | 1 | 0.8 | 1450 | 1.1 | 1.5 | 3 | ||

| C | 22 | 39 | 58 | 1 | 2.2 | 2900 | 5.5 | 7.5 | 11 | |

| 11.5 | 9 | 55 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| D | 18 | 20 | 58 | 1 | 2.2 | 2900 | 4 | 5.5 | 7.5 | |

| 9.5 | 7 | 55 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| TZC40-250 | A | 32 | 78 | 53 | 1 | 2.5 | 2900 | 18.5 | 22 | 30 |

| 16 | 19.5 | 49.5 | 1 | 0.8 | 1450 | 3 | 4 | 5.5 | ||

| B | 30 | 72 | 53 | 1 | 2.5 | 2900 | 15 | 18.5 | 30 | |

| 15 | 18 | 49.5 | 1 | 0.8 | 1450 | 2.2 | 3 | 4 | ||

| C | 24 | 60 | 53 | 1 | 2.5 | 2900 | 11 | 15 | 18.5 | |

| 12.5 | 14 | 49.5 | 1 | 0.8 | 1450 | 1.5 | 2.2 | 3 | ||

| D | 21 | 47 | 53 | 1 | 2.5 | 2900 | 7.5 | 11 | 15 | |

| 10.5 | 10 | 49.5 | 1 | 0.8 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZC40-315 | A | 42 | 115 | 46 | 2 | 1.3 | 2900 | 37 | 45 | 75 |

| 21 | 29 | 42 | 2 | 0.5 | 1450 | 5.5 | 7.5 | 11 | ||

| B | 40 | 107 | 46 | 2 | 1.3 | 2900 | 30 | 45 | 55 | |

| 20 | 26.5 | 42 | 2 | 0.5 | 1450 | 5.5 | 7.5 | 11 | ||

| C | 34 | 81 | 46 | 2 | 1.3 | 2900 | 22 | 30 | 45 | |

| 17.5 | 20 | 42 | 2 | 0.5 | 1450 | 4 | 5.5 | 7.5 | ||

| D | 29 | 61 | 46 | 2 | 1.3 | 2900 | 15 | 22 | 30 | |

| 15 | 15 | 42 | 2 | 0.5 | 1450 | 3 | 3 | 5.5 | ||

| TZC50-160 | A | 50 | 34 | 71 | 2 | 2.4 | 2900 | 11 | 15 | 15 |

| 25 | 8.4 | 69 | 1 | 0.8 | 1450 | 1.5 | 2.2 | 2.2 | ||

| B | 45 | 29 | 71 | 2 | 2.4 | 2900 | 7.5 | 11 | 15 | |

| 22.5 | 7 | 69 | 1 | 0.8 | 1450 | 1.5 | 1.5 | 2.2 | ||

| C | 38 | 22 | 71 | 2 | 2.4 | 2900 | 5.5 | 7.5 | 11 | |

| 19 | 5.5 | 69 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| D | 31 | 17 | 71 | 2 | 2.4 | 2900 | 3 | 4 | 5.5 | |

| 16.5 | 4 | 69 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| TZC50-200 | A | 62 | 52 | 68 | 2 | 2.6 | 2900 | 18.5 | 22 | 30 |

| 31 | 13 | 65.5 | 1 | 0.7 | 1450 | 3 | 3 | 4 | ||

| B | 56 | 46 | 68 | 2 | 2.6 | 2900 | 15 | 18.5 | 22 | |

| 28.5 | 11.5 | 65.5 | 1 | 0.7 | 1450 | 2.2 | 3 | 4 | ||

| C | 49 | 37 | 68 | 2 | 2.6 | 2900 | 11 | 15 | 18.5 | |

| 25 | 9 | 65.5 | 1 | 0.7 | 1450 | 1.5 | 2.2 | 3 | ||

| D | 43 | 28 | 68 | 2 | 2.6 | 2900 | 7.5 | 11 | 15 | |

| 22 | 7 | 65.5 | 1 | 0.7 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZC50-250 | A | 70 | 82 | 65 | 2 | 2.4 | 2900 | 30 | 37 | 55 |

| 35 | 20 | 62.5 | 2 | 0.7 | 1450 | 4 | 5.5 | 7.5 | ||

| B | 66 | 75 | 65 | 2 | 2.4 | 2900 | 30 | 37 | 45 | |

| 33 | 18.5 | 62.5 | 2 | 0.7 | 1450 | 4 | 5.5 | 7.5 | ||

| C | 60 | 60 | 65 | 2 | 2.4 | 2900 | 22 | 30 | 37 | |

| 30 | 15 | 62.5 | 2 | 0.7 | 1450 | 3 | 4 | 5.5 | ||

| D | 50 | 45 | 65 | 2 | 2.4 | 2900 | 15 | 18.5 | 22 | |

| 26 | 11 | 62.5 | 2 | 0.7 | 1450 | 2.2 | 3 | 3 | ||

| TZC50-315 | A | 87 | 115 | 56 | 3 | 2.1 | 2900 | 55 | 75 | 110 |

| 44 | 28 | 53 | 2 | 0.5 | 1450 | 11 | 11 | 15 | ||

| B | 80 | 100 | 56 | 3 | 2.1 | 2900 | 45 | 75 | 90 | |

| 40 | 24 | 53 | 2 | 0.5 | 1450 | 7.5 | 11 | 15 | ||

| C | 70 | 78 | 56 | 3 | 2.1 | 2900 | 30 | 45 | 55 | |

| 35 | 19 | 53 | 2 | 0.5 | 1450 | 5.5 | 7.5 | 11 | ||

| D | 57 | 57 | 56 | 3 | 2.1 | 2900 | 22 | 30 | 37 | |

| 30 | 14 | 53 | 2 | 0.5 | 1450 | 3 | 4 | 5.5 | ||

| TZC50-400 | A | 82 | 194 | 48 | 3 | 2 | 2900 | 110 | 160 | |

| 41 | 48 | 45 | 2 | 0.5 | 1450 | 15 | 22 | 30 | ||

| B | 78 | 175 | 48 | 3 | 2 | 2900 | 90 | 132 | 160 | |

| 39 | 43 | 45 | 2 | 0.5 | 1450 | 15 | 18.5 | 22 | ||

| C | 70 | 140 | 48 | 3 | 2 | 2900 | 75 | 90 | 132 | |

| 35 | 34 | 45 | 2 | 0.5 | 1450 | 11 | 15 | 18.5 | ||

| D | 60 | 102 | 48 | 3 | 2 | 2900 | 45 | 75 | 90 | |

| 30 | 25 | 45 | 2 | 0.5 | 1450 | 7.5 | 11 | 15 | ||

| TZC80-160 | A | 94 | 32 | 78 | 2 | 3 | 2900 | 15 | 18.5 | 30 |

| 47 | 8 | 76 | 2 | 0.8 | 1450 | 2.2 | 3 | 4 | ||

| B | 85 | 28 | 78 | 2 | 3 | 2900 | 11 | 15 | 18.5 | |

| 42 | 7 | 76 | 2 | 0.8 | 1450 | 2.2 | 2.2 | 3 | ||

| C | 76 | 23 | 78 | 2 | 3 | 2900 | 11 | 11 | 15 | |

| 38 | 5.5 | 76 | 2 | 0.8 | 1450 | 1.5 | 2.2 | 2.2 | ||

| D | 66 | 17 | 78 | 2 | 3 | 2900 | 5.5 | 7.5 | 11 | |

| 34 | 4 | 76 | 2 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| TZC80-200 | A | 103 | 54 | 76 | 1 | 3.2 | 2900 | 30 | 37 | |

| 51 | 13.5 | 74 | 4 | 0.8 | 1450 | 4 | 5.5 | 7.5 | ||

| B | 95 | 48 | 76 | 1 | 3.2 | 2900 | 22 | 30 | 37 | |

| 47 | 12 | 74 | 4 | 0.8 | 1450 | 3 | 4 | 5.5 | ||

| C | 84 | 38 | 76 | 1 | 3.2 | 2900 | 15 | 22 | 30 | |

| 41 | 9.5 | 74 | 4 | 0.8 | 1450 | 2.2 | 3 | 4 | ||

| D | 70 | 30 | 76 | 1 | 3.2 | 2900 | 11 | 15 | 22 | |

| 36 | 7.5 | 74 | 4 | 0.8 | 1450 | 1.5 | 2.2 | 3 | ||

| TZC80-250 | A | 127 | 82 | 74 | 2 | 3.5 | 2900 | 45 | 75 | 90 |

| 64 | 20 | 74 | 2 | 1.4 | 1450 | 7.5 | 11 | 15 | ||

| B | 120 | 76 | 74 | 2 | 3.5 | 2900 | 45 | 55 | 75 | |

| 60 | 19 | 74 | 2 | 1.4 | 1450 | 7.5 | 7.5 | 11 | ||

| C | 105 | 59 | 74 | 2 | 3.5 | 2900 | 30 | 45 | 55 | |

| 52 | 14.5 | 74 | 2 | 1.4 | 1450 | 4 | 5.5 | 7.5 | ||

| D | 87 | 45 | 74 | 2 | 3.5 | 2900 | 22 | 30 | 37 | |

| 46 | 11 | 74 | 2 | 1.4 | 1450 | 3 | 4 | 5.5 | ||

| TZC80-315 | A | 141 | 127 | 69 | 2 | 4 | 2900 | 90 | ||

| 70 | 33 | 69 | 2 | 1 | 1450 | 15 | 18.5 | 22 | ||

| B | 135 | 121 | 69 | 2 | 4 | 2900 | 75 | |||

| 66 | 30 | 69 | 2 | 1 | 1450 | 11 | 15 | 22 | ||

| C | 115 | 97 | 69 | 2 | 4 | 2900 | 55 | 75 | ||

| 56 | 24 | 69 | 2 | 1 | 1450 | 11 | 11 | 15 | ||

| D | 90 | 74 | 69 | 2 | 4 | 2900 | 37 | 45 | 75 | |

| 45 | 18 | 69 | 2 | 1 | 1450 | 5.5 | 7.5 | 11 | ||

| TZC80-400 | A | 171 | 187 | 61 | 3 | 3.5 | 2900 | 160 | ||

| 85 | 46 | 61 | 2 | 0.8 | 1450 | 22 | 30 | 45 | ||

| B | 159 | 170 | 61 | 3 | 3.5 | 2900 | 160 | |||

| 80 | 42 | 61 | 2 | 0.8 | 1450 | 18.5 | 30 | 37 | ||

| C | 135 | 130 | 61 | 3 | 3.5 | 2900 | 90 | 132 | ||

| 65 | 33 | 61 | 2 | 0.8 | 1450 | 15 | 18.5 | 30 | ||

| D | 116 | 95 | 61 | 3 | 3.5 | 2900 | 75 | 90 | 132 | |

| 53 | 25 | 61 | 2 | 0.8 | 1450 | 11 | 15 | 18.5 | ||

| TZC100-160 | A | 162 | 29 | 81 | 2 | 4.7 | 2900 | 22 | 30 | 37 |

| 81 | 7.2 | 81 | 2 | 1.4 | 1450 | 3 | 4 | 5.5 | ||

| B | 150 | 24 | 81 | 2 | 4.7 | 2900 | 15 | 22 | 30 | |

| 73 | 6 | 81 | 2 | 1.4 | 1450 | 2.2 | 3 | 4 | ||

| C | 130 | 17 | 81 | 2 | 4.7 | 2900 | 11 | 15 | 18.5 | |

| 63 | 4.3 | 81 | 2 | 1.4 | 1450 | 1.5 | 2.2 | 3 | ||

| D | 110 | 12 | 81 | 2 | 4.7 | 2900 | 7.5 | 11 | 15 | |

| 55 | 3 | 81 | 2 | 1.4 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZC100-200 | A | 193 | 50 | 81 | 2 | 3.7 | 2900 | 45 | 55 | 75 |

| 95 | 12.5 | 81 | 2 | 1 | 1450 | 5.5 | 7.5 | 11 | ||

| B | 180 | 44 | 81 | 2 | 3.7 | 2900 | 37 | 45 | 75 | |

| 90 | 10.5 | 81 | 2 | 1 | 1450 | 5.5 | 7.5 | 11 | ||

| C | 155 | 35 | 81 | 2 | 3.7 | 2900 | 30 | 37 | 45 | |

| 80 | 8.5 | 81 | 2 | 1 | 1450 | 4 | 5.5 | 7.5 | ||

| D | 135 | 26 | 81 | 2 | 3.7 | 2900 | 18.5 | 30 | 37 | |

| 70 | 6 | 81 | 2 | 1 | 1450 | 3 | 3 | 4 | ||

| TZC100-250 | A | 230 | 79 | 81 | 2 | 4 | 2900 | 75 | 90 | |

| 115 | 20 | 81 | 2 | 1 | 1450 | 11 | 15 | 18.5 | ||

| B | 218 | 73 | 81 | 2 | 4 | 2900 | 75 | 90 | ||

| 110 | 18 | 81 | 2 | 1 | 1450 | 11 | 11 | 15 | ||

| C | 190 | 58 | 81 | 2 | 4 | 2900 | 45 | 75 | 90 | |

| 100 | 14 | 81 | 2 | 1 | 1450 | 7.5 | 11 | 11 | ||

| D | 170 | 44 | 81 | 2 | 4 | 2900 | 37 | 45 | 75 | |

| 90 | 40 | 81 | 2 | 1 | 1450 | 5.5 | 7.5 | 7.5 | ||

| TZC100-315 | A | 250 | 126 | 78 | 2 | 5 | 2900 | 132 | ||

| 125 | 31 | 78 | 2 | 1.4 | 1450 | 18.5 | 30 | 37 | ||

| B | 240 | 120 | 78 | 2 | 5 | 2900 | 132 | 160 | ||

| 119 | 29 | 78 | 2 | 1.4 | 1450 | 18.5 | 22 | 30 | ||

| C | 203 | 97 | 78 | 2 | 5 | 2900 | 90 | 132 | 160 | |

| 104 | 24 | 78 | 2 | 1.4 | 1450 | 15 | 18.5 | 22 | ||

| D | 170 | 71 | 78 | 2 | 5 | 2900 | 75 | 75 | 110 | |

| 86 | 17.5 | 78 | 2 | 1.4 | 1450 | 11 | 11 | 15 | ||

| TZC100-400 | A | 300 | 194 | 74.5 | 3 | 6.4 | 2900 | |||

| 150 | 48 | 1.7 | 1450 | 37 | 45 | 75 | ||||

| B | 290 | 180 | 6.4 | 2900 | ||||||

| 145 | 44 | 1.7 | 1450 | 30 | 45 | 55 | ||||

| C | 260 | 145 | 6.4 | 2900 | ||||||

| 130 | 36 | 1.7 | 1450 | 22 | 30 | 45 | ||||

| D | 224 | 105 | 6.4 | 2900 | 110 | 160 | ||||

| 115 | 26 | 1.7 | 1450 | 15 | 22 | 30 | ||||

| TZC100-500 | A | 180 | 75 | 3 | 1.5 | 1450 | 75 | 90 | 110 | |

| B | 167 | 68 | 55 | 75 | 110 | |||||

| C | 142 | 53 | 37 | 55 | 75 | |||||

| D | 120 | 42 | 30 | 37 | 55 | |||||

| TZC150-200 | A | 320 | 44 | 83.5 | 2 | 6.4 | 2900 | 55 | 75 | |

| 160 | 11 | 83.5 | 2 | 1.7 | 1450 | 7.5 | 11 | 15 | ||

| B | 300 | 39 | 83.5 | 2 | 6.4 | 2900 | 45 | 75 | 90 | |

| 152 | 9.5 | 83.5 | 2 | 1.7 | 1450 | 7.5 | 11 | 15 | ||

| C | 265 | 30 | 83.5 | 2 | 6.4 | 2900 | 37 | 45 | 75 | |

| 140 | 7 | 83.5 | 2 | 1.7 | 1450 | 5.5 | 7.5 | 11 | ||

| D | 220 | 23 | 83.5 | 2 | 6.4 | 2900 | 22 | 30 | 45 | |

| 123 | 5 | 83.5 | 2 | 1.7 | 1450 | 3 | 4 | 5.5 | ||

| TZC150-250 | A | 390 | 74 | 82 | 3 | 6 | 2900 | 110 | 160 | |

| 195 | 18.5 | 82 | 2 | 1.4 | 1450 | 15 | 22 | 30 | ||

| B | 355 | 62 | 82 | 3 | 6 | 2900 | 90 | 110 | 160 | |

| 180 | 6 | 82 | 2 | 1.4 | 1450 | 15 | 18.5 | 22 | ||

| C | 325 | 46 | 82 | 3 | 6 | 2900 | 75 | 90 | 110 | |

| 160 | 11.5 | 82 | 2 | 1.4 | 1450 | 11 | 11 | 15 | ||

| TZC150-315 | A | 442 | 125 | 82.5 | 3 | 7 | 2900 | |||

| 220 | 32.5 | 81 | 3 | 1.7 | 1450 | 30 | 45 | 55 | ||

| B | 430 | 120 | 82.5 | 3 | 7 | 2900 | ||||

| 210 | 30 | 81 | 3 | 1.7 | 1450 | 30 | 37 | 55 | ||

| C | 372 | 94 | 82.5 | 3 | 7 | 2900 | 160 | |||

| 180 | 24 | 81 | 3 | 1.7 | 1450 | 22 | 30 | 37 | ||

| D | 310 | 68 | 82.5 | 3 | 7 | 2900 | 90 | 132 | 160 | |

| 150 | 17 | 81 | 3 | 1.7 | 1450 | 15 | 18.5 | 22 | ||

| TZC150-400 | A | 520 | 205 | 78.5 | 4 | 7 | 2900 | |||

| 260 | 51 | 77 | 3 | 1.8 | 1450 | 55 | 75 | 110 | ||

| B | 498 | 190 | 78.5 | 4 | 7 | 2900 | ||||

| 250 | 48 | 77 | 3 | 1.8 | 1450 | 55 | 75 | 90 | ||

| C | 453 | 151 | 78.5 | 4 | 7 | 2900 | ||||

| 225 | 38 | 77 | 3 | 1.8 | 1450 | 37 | 55 | 75 | ||

| D | 400 | 113 | 78.5 | 4 | 7 | 2900 | ||||

| 200 | 28 | 77 | 3 | 1.8 | 1450 | 30 | 37 | 55 | ||

| TZC150-500 | A | 300 | 77 | 74 | 3 | 2 | 1450 | 110 | 132 | |

| B | 283 | 72 | 74 | 3 | 2 | 1450 | 90 | 132 | 160 | |

| C | 233 | 59 | 74 | 3 | 2 | 1450 | 75 | 90 | 110 | |

| D | 208 | 45 | 74 | 3 | 2 | 1450 | 45 | 75 | 75 | |

| TZC150-560 | A | 335 | 104 | 74.5 | 4 | 2.4 | 1450 | 160 | ||

| B | 315 | 97 | 74.5 | 4 | 2.4 | 1450 | 132 | |||

| C | 260 | 80 | 74.5 | 4 | 2.4 | 1450 | 90 | 132 | 160 | |

| D | 216 | 60 | 74.5 | 4 | 2.4 | 1450 | 75 | 90 | 110 | |

| TZC150-630 | A | 360 | 115 | 63 | 4 | 2.4 | 1450 | |||

| B | 338 | 105.5 | ||||||||

| C | 274 | 82 | 132 | 160 | ||||||

| D | 220 | 60 | 75 | 110 | 160 | |||||

| TZC200-250 | A | 610 | 72 | 84.5 | 3 | 9 | 2900 | 160 | ||

| 305 | 17.5 | 83.5 | 3 | 2.4 | 1450 | 22 | 30 | 45 | ||

| B | 580 | 65 | 84.5 | 3 | 9 | 2900 | 160 | |||

| 290 | 16 | 83.5 | 3 | 2.4 | 1450 | 18.5 | 30 | 37 | ||

| C | 520 | 47 | 84.5 | 3 | 9 | 2900 | 110 | 132 | 160 | |

| 260 | 12 | 83.5 | 3 | 2.4 | 1450 | 15 | 18.5 | 30 | ||

| D | 470 | 32 | 84.5 | 3 | 9 | 2900 | 75 | 90 | 110 | |

| 240 | 8 | 83.5 | 3 | 2.4 | 1450 | 11 | 15 | 15 | ||

| TZC200-315 | A | 710 | 122 | 85.5 | 4 | 8.6 | 2900 | |||

| 350 | 30 | 84.5 | 3 | 2 | 1450 | 45 | 55 | 75 | ||

| B | 680 | 114 | 85.5 | 4 | 8.6 | 2900 | ||||

| 340 | 29 | 84.5 | 3 | 2 | 1450 | 37 | 55 | 75 | ||

| C | 600 | 87 | 85.5 | 4 | 8.6 | 2900 | ||||

| 300 | 22 | 84.5 | 3 | 2 | 1450 | 30 | 37 | 55 | ||

| D | 480 | 65 | 85.5 | 4 | 8.6 | 2900 | 132 | |||

| 250 | 15 | 84.5 | 3 | 2 | 1450 | 18.5 | 22 | 30 | ||

| TZC200-400 | A | 850 | 203 | 82 | 5 | 13 | 2900 | |||

| 426 | 50 | 81 | 3 | 3.5 | 1450 | 90 | 110 | 160 | ||

| B | 830 | 150 | 82 | 5 | 13 | 2900 | ||||

| 410 | 47 | 81 | 3 | 3.5 | 1450 | 75 | 110 | 132 | ||

| C | 750 | 145 | 82 | 5 | 13 | 2900 | ||||

| 370 | 36.5 | 81 | 3 | 3.5 | 1450 | 55 | 75 | 110 | ||

| D | 670 | 106 | 82 | 5 | 13 | 2900 | ||||

| 332 | 27 | 81 | 3 | 3.5 | 1450 | 45 | 55 | 75 | ||

| TZC200-500 | A | 495 | 84 | 81 | 4 | 2.9 | 1450 | |||

| B | 470 | 79 | 160 | |||||||

| C | 400 | 63 | 110 | 160 | ||||||

| D | 330 | 48 | 75 | 90 | 132 | |||||

| TZC200-560 | A | 540 | 105 | 79.5 | 5 | 3 | 1450 | |||

| B | 510 | 98 | ||||||||

| C | 460 | 81 | 160 | |||||||

| D | 350 | 62 | 110 | 132 | ||||||

| TZC200-630 | A | 580 | 132 | 77.5 | 5 | 3.5 | 1450 | |||

| B | 550 | 125 | ||||||||

| C | 468 | 100 | ||||||||

| D | 372 | 75 | 132 | |||||||

| TZC250-315 | A | 545 | 27 | 86.5 | 3 | 2.9 | 1450 | 55 | 75 | 110 |

| B | 528 | 25 | 55 | 75 | 90 | |||||

| C | 480 | 19 | 37 | 55 | 75 | |||||

| D | 434 | 13 | 30 | 37 | 45 | |||||

| TZC250-400 | A | 660 | 49 | 87.5 | 5 | 3.2 | 1450 | 132 | 160 | |

| B | 630 | 46 | 110 | 160 | ||||||

| C | 565 | 36 | 75 | 110 | 160 | |||||

| D | 500 | 24 | 55 | 75 | 90 | |||||

| TZC250-500 | A | 800 | 82 | 83 | 5 | 5 | 1450 | |||

| B | 770 | 76 | ||||||||

| C | 700 | 58 | 160 | |||||||

| D | 630 | 42 | 110 | 160 | ||||||

| TZC250-560 | A | 860 | 106 | 82 | 5 | 4.2 | 1450 | |||

| B | 830 | 98 | ||||||||

| C | 760 | 78 | ||||||||

| D | 665 | 57 | 160 | |||||||

| TZC250-630 | A | 855 | 128 | 80.5 | 6 | 4.2 | 1450 | |||

| B | 816 | 119 | ||||||||

| C | 720 | 96 | ||||||||

| D | 625 | 71 | ||||||||

| TZC300-400 | A | 1050 | 48 | 87 | 4 | 5.8 | 1450 | |||

| B | 1010 | 45 | 160 | |||||||

| C | 900 | 34 | 132 | 160 | 160 | |||||

| D | 780 | 26 | 90 | 132 | ||||||

| TZC300-500 | A | 1240 | 78 | 88 | 5 | 5.8 | 1450 | |||

| B | 1170 | 75 | ||||||||

| C | 1015 | 57 | ||||||||

| D | 870 | 42 | 160 | |||||||

| TZC300-560 | A | 1340 | 104 | 87 | 6 | 5.2 | 1450 | |||

| B | 1280 | 9 | ||||||||

| C | 1140 | 77 | ||||||||

| D | 950 | 56 | ||||||||

| TZC300-630 | A | 1450 | 132 | 85 | 6 | 5.5 | 1450 | |||

| B | 1375 | 125 | ||||||||

| C | 1170 | 100 | ||||||||

| D | 950 | 75 | ||||||||

| TZC400-500 | A | 1870 | 74 | 88 | 6 | 6.3 | 1450 | |||

| B | 1800 | 70 | ||||||||

| C | 1520 | 52 | ||||||||

| D | 1300 | 38 | ||||||||

| TZC400-560 | A | 2040 | 98 | 88 | 6 | 7.5 | 1450 | |||

| B | 1950 | 91 | ||||||||

| C | 1760 | 74 | ||||||||

| D | 1500 | 54 | ||||||||

| TZC400-630 | A | 2390 | 125 | 88 | 7 | 8.3 | 1450 | |||

| B | 2280 | 117 | ||||||||

| C | 1960 | 95 | ||||||||

| D | 1610 | 70 | ||||||||

Previous product:TI chemical process centrifugal pump

Next Product:TZE petrochemical process centrifugal pump