|

|

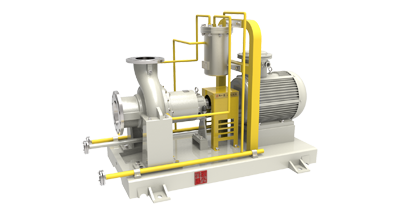

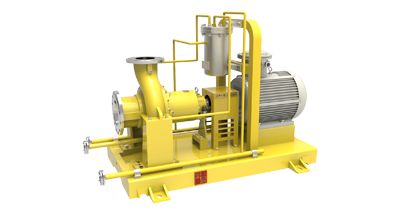

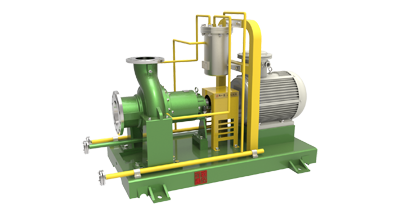

| TCE no leakage petrochemical magnetic pump(Flush with API610) |

Selection of color |

||||||

|

||||||

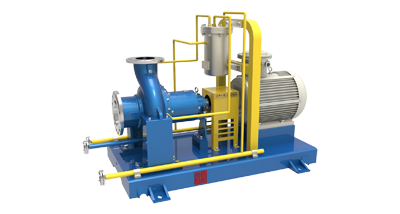

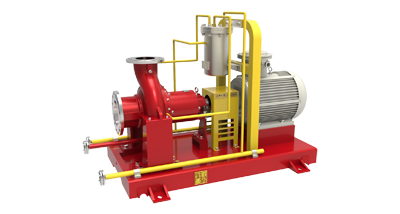

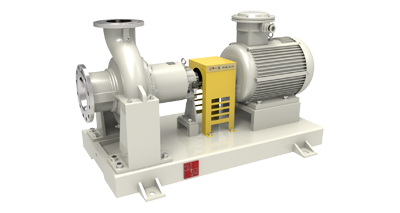

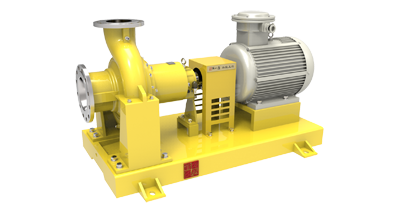

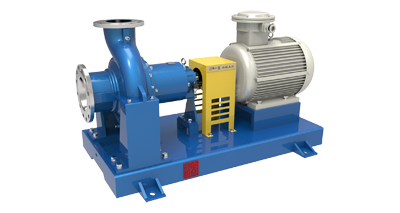

| TCE no leakage petrochemical magnetic pump |

Selection of color |

||||||

|

||||||

| MEANING | TCE25-200 |

| T | Code of enterprise |

| C | Magnetic pump |

| E | Center support |

| 25 | The outlet dia is 25mm |

| 200 | Nominal dia of impeller is 200mm |

一、Product Introduction:

Material:304、316、904L, dual-phase steel, titanium alloy, hastelloy, etc.

Standard:API685-2000,foot support for TCA series, and center support for TCE series.

FEATURES:

1. The world advanced performance and structure of magnetic driven device. Our produced magnetic pumps use unique magnetic devices of intensive type, magnetic accumulation and magnetic circuit pulling coupling. Compared with driven devices of dispersing type, gap-structure and attractive magnetic circuit coupling which similar products of world developed countries widely used, this series pumps has advantages of small bulk, big torque, small eddy, high driving efficiency and super reliability, getting rid of slipping and other defects.

2. The efficiency of this series pump is generally higher 5%-10% than similar products of world developed countries. Our company utilized patented technologies and proprietary technologies to optimally design the magnetic driven devices, the structure and all components. Combing with proper processes and manufacturing, all kinds of efficiency loss are reduced to the lowest level, implement the roundly same efficiency between centrifugal magnetic pump and shaft sealing magnetic pump.

3. Low natural wear rate and long maintenance-free period. The axial force of this series pumps is almost zero which owe to unique axial force balance system. The axial force balance system can make the lowest friction between sliding shaft and thrust shaft of ends.

4. The vibration and noise of this series pumps is lower than similar foreign products’.

Application: Widely applied to convey clean liquids of no particles and proportion of no more than 1.84 in many fields or processes like petroleum, chemical, medicine, printing and dyeing, etc. Particularly be applicable to delivery media of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc. No leakage pump is the ideal green chemical equipment, which will make high economic benefit and social benefit for petroleum, chemical, medicine, printing and dyeing industries of protecting environment, safety in production, eliminating pollution, labor protection, increasing production and decreasing expending. TCA/E series pumps is the standard no leakage centrifugal pump, which can replace shaft sealing centrifugal pumps and canned pumps.

Performance range: Design pressure: 2.5Mpa for TCA series, 5.0Mpa for TCE series. Flow: 5.5-2000m3/h, Head: 16-168m, Power: 1.5-900kw

Applicable temperature: -30~200℃ for TCA series, -30~350℃ for TCE series.

The optional accessories: preventive idling running device, monitoring of leakage device, monitoring of temperature device.

Notes: Please indicate during ordering if the proportion of delivering media is larger than 1.3mg/cm3. No idle running. No delivering media with particles or crystalline.

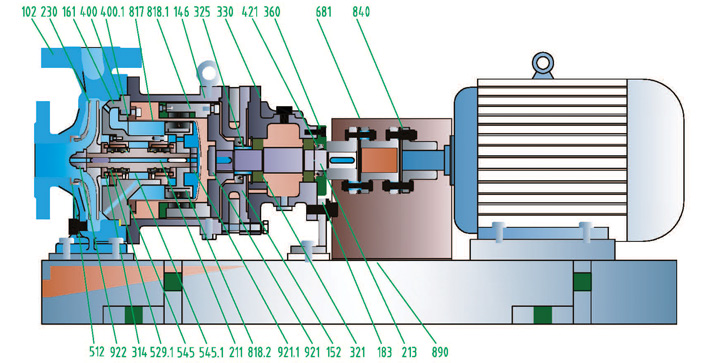

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 102.pump body | 304/316/316L | 545.1bearing bushing | 304/316/316L | 545.slide bearing | SSic/hard alloy |

| 230.impeller | 304/316/316L | 890.base plate | HT200/45 | 529.1bearing sleeve | SSic/hard alloy |

| 161.pump cover | 304/316/316L | 231.driven plate | 2Cr13 | 314.thrust collar | SSic/hard alloy |

| 817.distance sleeve | 316L/TA2/HC276 | 183.bracket plate | HT 200 | 922.impeller nut | 304/316/316L |

| 818.1outer magnet component | permenant magnet/ZG | 152.cooling bracket | 45 | 512.wearing ring | 304/316/316L |

| 146.bracket | HT 200 | 921.locknut | 45 | 321.ball bearing | Gcr15 |

| 330.bearing box | HT 200 | 921.1locknut | 304/316/316L | 525.bearing bushing | 45 |

| 360.bearing gland | HT 200 | 812.2rotor assembly | permenant magnet/304/316/316L | 400.sealing gasket | PTFE |

| 681.shield | 45/Aluminium | 211pump shaft | 304/316/316L | 4001.sealing gasket | PTFE |

| 840.coupling | HT200/45 | 521oil seal | Fluorubber |

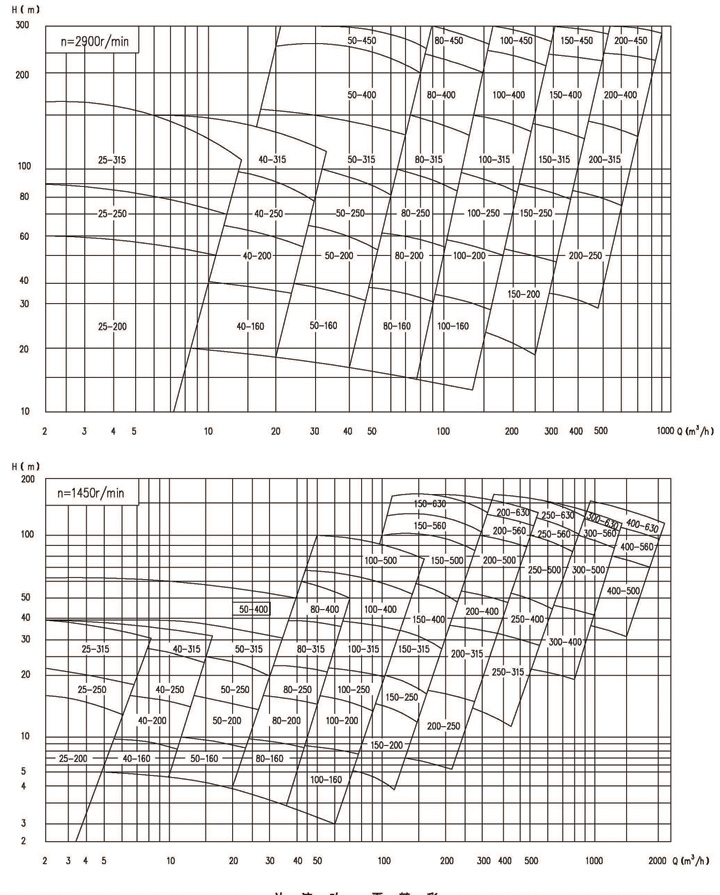

三、Performance Curve:

四、Performance data sheet:

| Type | Impeller | Flow | Head | Speed | Efficiencyη | NPSHr | Shaft power | Motor | |

| Type | Power(KW) | ||||||||

| 25-200 | A | 11.5 | 49 | 2950 | 42 | 1.6 | 3.6 | YB132S1-2 | 5.5 |

| B | 10.5 | 42 | 2950 | 41 | 1.4 | 2.9 | YB112M-2 | 4 | |

| C | 9 | 36 | 2950 | 39.5 | 1.2 | 2.2 | YB100L-2 | 3 | |

| D | 7.5 | 28 | 2950 | 37.5 | 1.1 | 1.5 | YB90L-2 | 2.2 | |

| E | 5.5 | 16 | 2950 | 35 | 1.1 | 0.7 | YB90S-2 | 1.5 | |

| 25-250 | A | 12 | 75 | 2950 | 40 | 2.4 | 7.8 | YB160M1-2 | 11 |

| B | 10.5 | 65 | 2950 | 38 | 2.4 | 7.2 | YB160M1-2 | 11 | |

| C | 10 | 50 | 2950 | 33 | 2.2 | 4.2 | YB132S2-2 | 7.5 | |

| D | 9 | 30 | 2950 | 31 | 2.1 | 3.5 | YB132S1-2 | 5.5 | |

| 25-315 | A | 18 | 130 | 2950 | 38 | 2.4 | 24.2 | YB200L1-2 | 30 |

| B | 17 | 115 | 2950 | 38 | 2.4 | 16.5 | YB180M-2 | 22 | |

| C | 16 | 100 | 2950 | 33 | 2.1 | 15.2 | YB160L-2 | 18.5 | |

| D | 15 | 90 | 2950 | 30 | 2.1 | 11 | YB160M2-2 | 15 | |

| 40-160 | A | 28 | 33 | 2950 | 62 | 3 | 4.1 | YB132S1-2 | 7.5 |

| B | 25.6 | 29 | 2950 | 61 | 2.5 | 3.3 | YB132S1-2 | 5.5 | |

| C | 22 | 22 | 2950 | 58 | 1.5 | 2.3 | YB12M-2 | 4 | |

| D | 20 | 16 | 2950 | 55 | 1.5 | 1.6 | YB90L-2 | 2.2 | |

| 40-200 | A | 29 | 53 | 2950 | 58 | 2.2 | 7.2 | YB160M1-2 | 11 |

| B | 26 | 47 | 2950 | 58 | 1.7 | 5.9 | YB132S2-2 | 7.5 | |

| C | 22 | 39 | 2950 | 56 | 1.3 | 4.2 | YB132S1-2 | 5.5 | |

| D | 18 | 30 | 2950 | 53 | 1.2 | 2.8 | YB112M-2 | 4 | |

| 40-250 | A | 32 | 78 | 2950 | 53 | 2.4 | 12.8 | YB160L-2 | 18.5 |

| B | 30 | 72 | 2950 | 52.5 | 2.2 | 11.2 | YB160M2-2 | 15 | |

| C | 24 | 60 | 2950 | 50.5 | 1.7 | 7.8 | YB160M1-2 | 11 | |

| D | 21 | 47 | 2950 | 48 | 1.7 | 5.6 | YB132S2-2 | 7.5 | |

| 40-315 | A | 42 | 115 | 2950 | 46 | 1.3 | 28.6 | YB200L2-2 | 37 |

| B | 40 | 107 | 2950 | 45 | 1.2 | 25.9 | YB200L-2 | 30 | |

| C | 34 | 81 | 2950 | 42.5 | 1 | 17.6 | YB180M-2 | 22 | |

| D | 29 | 61 | 2950 | 40.5 | 0.9 | 11.9 | YB160M2-2 | 15 | |

| 50-160 | A | 50 | 34 | 2950 | 71 | 2.4 | 6.5 | YB160M1-2 | 11 |

| B | 45 | 29 | 2950 | 70 | 1.8 | 5.1 | YB132S2-2 | 7.5 | |

| C | 38 | 22 | 2950 | 68 | 1.5 | 3.3 | YB132S1-2 | 5.5 | |

| D | 31 | 17 | 2950 | 65 | 1.5 | 3.2 | YB100L-2 | 3 | |

| 50-200 | A | 62 | 52 | 2950 | 68 | 2.5 | 12.9 | YB160L-2 | 18.5 |

| B | 56 | 46 | 2950 | 67 | 2.2 | 10.5 | YB160M2-2 | 15 | |

| C | 49 | 37 | 2950 | 65 | 1.8 | 7.6 | YB160M1-2 | 11 | |

| D | 43 | 28 | 2950 | 60 | 1.8 | 5.5 | YB132S2-2 | 7.5 | |

| 50-250 | A | 70 | 82 | 2950 | 65 | 2.5 | 24 | YB180L1-2 | 30 |

| B | 66 | 75 | 2950 | 64 | 2.2 | 21.1 | YB180L1-2 | 30 | |

| C | 60 | 60 | 2950 | 62 | 2 | 15.8 | YB180M-2 | 18.5 | |

| D | 50 | 45 | 2950 | 60 | 1.7 | 10.2 | YB160M2-2 | 15 | |

| 50-315 | A | 87 | 115 | 2950 | 56 | 2.5 | 48.7 | YB250M-2 | 55 |

| B | 80 | 100 | 2950 | 55 | 2 | 39.6 | YB225M-2 | 45 | |

| C | 70 | 78 | 2950 | 54 | 1.6 | 27.5 | YB200L2-2 | 37 | |

| D | 57 | 57 | 2950 | 50 | 1.4 | 17.7 | YB180M-2 | 22 | |

| 50-400 | A | 82 | 194 | 2950 | 48 | 2.2 | 90.3 | YB315S-2 | 110 |

| B | 78 | 175 | 2950 | 47 | 2 | 79.1 | YB280M-2 | 90 | |

| C | 70 | 140 | 2950 | 46 | 1.8 | 58 | YB280S-2 | 75 | |

| D | 60 | 102 | 2950 | 43 | 1.6 | 38.8 | YB225M-2 | 45 | |

| 50-450 | A | 135 | 250 | 2950 | 52 | 5.2 | 176 | YB315L2-2 | 200 |

| B | 125 | 220 | 2950 | 52 | 4.5 | 144 | YB315L1-2 | 160 | |

| C | 115 | 186 | 2950 | 51 | 3.8 | 114 | YB315M-2 | 132 | |

| D | 100 | 158 | 2950 | 50.5 | 3.2 | 85 | YB315S-2 | 110 | |

| E | 95 | 130 | 2950 | 50 | 3 | 67 | YB280M-2 | 90 | |

| 80-160 | A | 94 | 32 | 2950 | 78 | 3 | 10.5 | YB160M2-2 | 15 |

| B | 85 | 28 | 2950 | 77 | 2.7 | 8.4 | YB160M1-2 | 15 | |

| C | 76 | 23 | 2950 | 76 | 2.5 | 6.3 | YB160M1-2 | 11 | |

| D | 66 | 17 | 2950 | 71 | 2.3 | 4.3 | YB132S1-2 | 7.5 | |

| 80-200 | A | 103 | 54 | 2950 | 76 | 3.2 | 19.9 | YB200L1-2 | 30 |

| B | 95 | 48 | 2950 | 75 | 3 | 16.6 | YB180M-2 | 22 | |

| C | 84 | 38 | 2950 | 72 | 3 | 12.1 | YB160M2-2 | 18.5 | |

| D | 70 | 31 | 2950 | 67 | 2.8 | 8.8 | YB160M1-2 | 15 | |

| 80-250 | A | 127 | 82 | 2950 | 74 | 4.2 | 38.3 | YB225M-2 | 45 |

| B | 120 | 76 | 2950 | 73 | 3.8 | 34 | YB225M-2 | 45 | |

| C | 105 | 59 | 2950 | 72 | 3.5 | 23.4 | YB200L1-2 | 30 | |

| D | 87 | 45 | 2950 | 66 | 3.5 | 16.2 | YB180M-2 | 22 | |

| 80-315 | A | 141 | 127 | 2950 | 69 | 4.3 | 70.7 | YB280M-2 | 90 |

| B | 135 | 121 | 2950 | 68 | 4 | 65.4 | YB280S-2 | 75 | |

| C | 115 | 97 | 2950 | 66 | 3.2 | 46 | YB250M-2 | 55 | |

| D | 90 | 74 | 2950 | 61 | 3 | 29.7 | YB200L2-2 | 37 | |

| 80-400 | A | 171 | 187 | 2950 | 61 | 4 | 142.8 | YB315L-2 | 160 |

| B | 159 | 170 | 2950 | 61 | 3.5 | 120.7 | YB315L1-2 | 132 | |

| C | 136 | 130 | 2950 | 57 | 2.4 | 84.5 | YB315S-2 | 110 | |

| D | 116 | 95 | 2950 | 51 | 2.9 | 58.8 | YB280S-2 | 75 | |

| 80-450 | A | 200 | 230 | 2950 | 59 | 5.2 | 212.2 | YB355M2-2 | 250 |

| B | 180 | 210 | 2950 | 58 | 4.3 | 177.4 | YB315L1-2 | 200 | |

| C | 165 | 195 | 2950 | 57.5 | 3.8 | 152.3 | YB355S1-2 | 185 | |

| D | 155 | 160 | 2950 | 56 | 3.5 | 120.6 | YB315L1-2 | 160 | |

| E | 140 | 130 | 2950 | 55 | 4 | 90.1 | YB315S-2 | 110 | |

| 100-160 | A | 162 | 29 | 2950 | 81 | 4.3 | 15.8 | YB180M-2 | 22 |

| B | 150 | 24 | 2950 | 80 | 3.6 | 12.3 | YB160M2-2 | 18.5 | |

| C | 130 | 17 | 2950 | 78 | 3 | 7.7 | YB160M1-2 | 15 | |

| D | 110 | 12 | 2950 | 71 | 3 | 5.1 | YB132S2-2 | 11 | |

| 100-200 | A | 193 | 50 | 2950 | 81 | 3.1 | 32.4 | YB225M-2 | 45 |

| B | 180 | 44 | 2950 | 80 | 3 | 27 | YB200L2-2 | 37 | |

| C | 155 | 35 | 2950 | 77 | 2.8 | 19.2 | YB200L1-2 | 30 | |

| D | 135 | 26 | 2950 | 72 | 2.8 | 13.3 | YB160L-2 | 18.5 | |

| 100-250 | A | 230 | 79 | 2950 | 81 | 4.5 | 61.1 | YB280S-2 | 75 |

| B | 218 | 73 | 2950 | 80 | 4 | 54.2 | YB280S-2 | 75 | |

| C | 190 | 58 | 2950 | 79 | 4 | 38 | YB225M-2 | 55 | |

| D | 170 | 44 | 2950 | 78 | 4 | 26.1 | YB200L2-2 | 37 | |

| 100-315 | A | 250 | 126 | 2950 | 75 | 3.8 | 114.4 | YB315M-2 | 132 |

| B | 240 | 120 | 2950 | 75 | 3.6 | 104.6 | YB315M-2 | 132 | |

| C | 203 | 97 | 2950 | 71 | 2.8 | 75.5 | YB280M-2 | 90 | |

| D | 170 | 71 | 2950 | 66 | 2.5 | 49.8 | YB280S-2 | 75 | |

| 100-400 | A | 300 | 194 | 2950 | 71 | 4.5 | 223.2 | YB355L1-2 | 250 |

| B | 290 | 180 | 2950 | 71 | 5.3 | 200.2 | YB355M2-2 | 220 | |

| C | 260 | 145 | 2950 | 69 | 4.9 | 148.8 | YB315L-2 | 185 | |

| D | 224 | 105 | 2950 | 66 | 5.7 | 97 | YB315S-2 | 132 | |

| 100-450 | A | 328 | 258 | 2950 | 70 | 6.1 | 329.1 | 440 | |

| B | 310 | 242 | 2950 | 70 | 5.5 | 291.7 | 355 | ||

| C | 260 | 200 | 2950 | 69 | 4.6 | YB355M2-2 | 250 | ||

| D | 200 | 150 | 2950 | 66 | 5.5 | 123.7 | YB315L1-2 | 160 | |

| 150-200 | A | 320 | 44 | 2950 | 83.5 | 6.3 | 46 | YB250M-2 | 55 |

| B | 300 | 39 | 2950 | 82 | 5.7 | 39 | YB225M-2 | 45 | |

| C | 265 | 30 | 2950 | 77 | 4.3 | 28 | YB200L2-2 | 37 | |

| D | 220 | 23 | 2950 | 73 | 4.2 | 19 | YB200L1-2 | 30 | |

| 150-250 | A | 390 | 74 | 2950 | 82 | 5.5 | 96 | Y315S-2 | 110 |

| B | 355 | 62 | 2950 | 80 | 5 | 75 | Y280M-2 | 90 | |

| C | 325 | 46 | 2950 | 76 | 5 | 53 | Y280S-2 | 75 | |

| 150-315 | A | 442 | 125 | 2950 | 82.5 | 7 | 182 | Y355M1-2 | 220 |

| B | 430 | 120 | 2950 | 82 | 6.8 | 172 | Y355M1-2 | 220 | |

| C | 372 | 94 | 2950 | 79 | 6 | 122 | Y315L1-2 | 160 | |

| D | 310 | 68 | 2950 | 75 | 6 | 76.5 | Y280M-2 | 90 | |

| 150-400 | A | 520 | 205 | 2950 | 78.5 | 7 | 370 | YB450M1-2 | 450 |

| B | 498 | 190 | 2950 | 78 | 6.7 | 330 | YB355L3-2 | 355 | |

| C | 453 | 151 | 2950 | 75 | 6.5 | 245 | YB355L1-2 | 280 | |

| D | 400 | 113 | 2950 | 73 | 6 | 169 | YB355S2-2 | 200 | |

| 150-450 | A | 548 | 260 | 2950 | 75 | 8 | 517.1 | 630 | |

| B | 252 | 245 | 2950 | 76 | 7 | 466.9 | 560 | ||

| C | 460 | 208 | 2950 | 73 | 6 | 356.8 | 400 | ||

| D | 360 | 140 | 2950 | 70 | 5.2 | 196 | YB355M1-2 | 200 | |

| 200-250 | A | 610 | 72 | 2950 | 84.5 | 9.2 | 142 | YB355S1-2 | 185 |

| B | 580 | 65 | 2950 | 84 | 8.2 | 122 | YB315L1-2 | 160 | |

| C | 520 | 47 | 2950 | 81 | 7.5 | 82.2 | YB315S2-2 | 110 | |

| D | 470 | 32 | 2950 | 78 | 6.5 | 52.2 | YB280S-2 | 75 | |

| 200-315 | A | 710 | 112 | 2950 | 85.5 | 9.5 | 276 | YB355L2-2 | 315 |

| B | 680 | 114 | 2950 | 85 | 8.5 | 251 | YB355L1-2 | 280 | |

| C | 600 | 87 | 2950 | 82 | 7.5 | 176 | YB355S2-2 | 200 | |

| D | 480 | 65 | 2950 | 77 | 6.5 | 110 | YB315M-2 | 132 | |

| 200-400 | A | 850 | 203 | 2950 | 82 | 13.5 | 573 | YB560M1-2 | 630 |

| B | 830 | 190 | 2950 | 81 | 12 | 530 | YB560M1-2 | 630 | |

| C | 750 | 145 | 2950 | 79 | 11 | 375 | YB450M1-2 | 450 | |

| D | 670 | 106 | 2950 | 76 | 11 | 255 | YB355L2-2 | 315 | |

| 200-450 | A | 940 | 255 | 2950 | 80 | 13 | 573 | 900 | |

| B | 880 | 240 | 2950 | 80 | 12 | 530 | 800 | ||

| C | 780 | 200 | 2950 | 78.5 | 9.1 | 377 | 630 | ||

| D | 600 | 140 | 2950 | 75 | 10 | 256 | 335 | ||

| 25-200 | A | 5.8 | 12 | 1475 | 38 | 0.7 | 0.5 | YB90S-4 | 1.1 |

| B | 5.4 | 11 | 1475 | 37.5 | 0.6 | 0.43 | YB90S-4 | 1.1 | |

| C | 4.6 | 8.5 | 1475 | 36.5 | 0.5 | 0.29 | YB90S-4 | 1.1 | |

| D | 4 | 6.5 | 1475 | 35 | 0.5 | 0.2 | YB90S-4 | 1.1 | |

| E | 3 | 4 | 1475 | 30 | 0.5 | 0.11 | YB90S-4 | 1.1 | |

| 25-250 | A | 8 | 17 | 1475 | 30 | 0.7 | 1.5 | YB100L1-4 | 2.2 |

| B | 7 | 16 | 1475 | 28 | 0.7 | 1.4 | YB100L1-4 | 2.2 | |

| C | 7.5 | 11 | 1475 | 23 | 0.7 | 1.3 | YB100L1-4 | 2.2 | |

| D | 6.5 | 6.5 | 1475 | 20 | 0.6 | 0.72 | YB90S-4 | 1.1 | |

| 25-315 | A | 10 | 31 | 1475 | 30 | 0.4 | 6 | YB112M-4 | 4 |

| B | 9 | 30 | 1475 | 26 | 0.4 | 2.7 | YB112M-4 | 4 | |

| C | 8 | 25 | 1475 | 25 | 0.38 | 2.3 | YB100L2-4 | 3 | |

| D | 7 | 22.5 | 1475 | 24 | 0.35 | 1.6 | YB100L1-4 | 2.2 | |

| 40-160 | A | 14 | 8.25 | 1475 | 59 | 0.8 | 0.5 | YB80M-4 | 0.75 |

| B | 12 | 7.5 | 1475 | 58 | 0.7 | 0.4 | YB80M-4 | 0.75 | |

| C | 10 | 6 | 1475 | 56 | 0.6 | 0.3 | YB80M-4 | 0.75 | |

| D | 8 | 4.5 | 1475 | 53 | 0.45 | 0.2 | YB80M-4 | 0.75 | |

| 40-200 | A | 14.5 | 13.2 | 1475 | 55 | 0.8 | 0.9 | YB90L-4 | 1.5 |

| B | 12.5 | 12 | 1475 | 53 | 0.65 | 0.8 | YB90L-4 | 1.1 | |

| C | 11 | 9.5 | 1475 | 51 | 0.7 | 0.6 | YB580M2-4 | 0.75 | |

| D | 9.5 | 7.8 | 1475 | 48 | 0.8 | 0.4 | YB580M2-4 | 0.75 | |

| 40-250 | A | 16 | 19.5 | 1475 | 49.5 | 0.75 | 1.7 | YB100L2-4 | 3 |

| B | 15 | 18 | 1475 | 49 | 0.65 | 1.5 | YB100L1-4 | 2.2 | |

| C | 12.5 | 14 | 1475 | 46 | 0.6 | 1.1 | YB90L-4 | 1.5 | |

| D | 10.5 | 11 | 1475 | 44 | 0.5 | 0.7 | YB90S-4 | 1.1 | |

| 40-315 | A | 21 | 29 | 1475 | 42 | 0.5 | 3.9 | YB132S-4 | 5.5 |

| B | 20 | 26.5 | 1475 | 40.5 | 0.5 | 3.6 | YB132S-4 | 5.5 | |

| C | 17.5 | 20 | 1475 | 37 | 0.5 | 2.6 | YB112M-4 | 4 | |

| D | 15 | 15 | 1475 | 35 | 0.5 | 1.8 | YB100L2-4 | 3 | |

| 50-160 | A | 25 | 8.5 | 1475 | 69 | 1 | 0.8 | YB90S-4 | 1.1 |

| B | 22 | 7.5 | 1475 | 66.5 | 1 | 0.7 | YB90S-4 | 1.1 | |

| C | 19 | 5.5 | 1475 | 64 | 1 | 0.4 | YB80M2-4 | 0.75 | |

| D | 15 | 4.5 | 1475 | 62 | 1 | 0.3 | YB80M2-4 | 0.75 | |

| 50-200 | A | 31 | 13 | 1475 | 65.5 | 0.75 | 1.7 | YB100L1-4 | 2.2 |

| B | 29 | 11.5 | 1475 | 65.5 | 0.6 | 1.4 | YB100L1-4 | 2.2 | |

| C | 26 | 9 | 1475 | 62 | 0.5 | 1 | YB90L-4 | 1.5 | |

| D | 22 | 7 | 1475 | 60 | 0.5 | 0.7 | YB90S-4 | 1.1 | |

| 50-250 | A | 35 | 20 | 1475 | 62.5 | 0.65 | 3.1 | YB112M-4 | 4 |

| B | 33 | 18.5 | 1475 | 62 | 0.6 | 2.7 | YB112M-4 | 4 | |

| C | 30 | 15 | 1475 | 61 | 0.5 | 2 | YB100L2-4 | 3 | |

| D | 26 | 11 | 1475 | 59 | 0.5 | 1.3 | YB100L1-4 | 2.2 | |

| 50-315 | A | 44 | 28 | 1475 | 53 | 0.5 | 6.3 | YB160M-4 | 11 |

| B | 40 | 24 | 1475 | 52.5 | 0.5 | 5 | YB132M-4 | 7.5 | |

| C | 35 | 19 | 1475 | 52 | 0.5 | 3.5 | YB132S-4 | 5.5 | |

| D | 30 | 14 | 1475 | 50 | 0.5 | 2.3 | YB112M-4 | 4 | |

| 50-400 | A | 41 | 48 | 1475 | 45 | 0.5 | 11.9 | YB160L-4 | 15 |

| B | 39 | 43 | 1475 | 44 | 0.5 | 10.4 | YB160L-4 | 15 | |

| C | 35 | 34 | 1475 | 43 | 0.5 | 7.5 | YB160M-4 | 11 | |

| D | 30 | 25 | 1475 | 42 | 0.55 | 4.9 | YB132M-4 | 7.5 | |

| 50-460 | A | 68 | 63 | 1475 | 49 | 1.5 | 23.8 | YB200L-4 | 30 |

| B | 62 | 55 | 1475 | 49 | 1.2 | 18.9 | YB200L-4 | 30 | |

| C | 54 | 47.5 | 1475 | 48 | 1 | 14.5 | YB180L-4 | 22 | |

| D | 50 | 40 | 1475 | 47 | 0.8 | 11.6 | YB180M-4 | 18.5 | |

| E | 40 | 35 | 1475 | 46 | 0.6 | 8.3 | YB180M-4 | 11 | |

| 80-160 | A | 47 | 8.3 | 1475 | 76 | 0.75 | 1.4 | YB100L1-4 | 2.2 |

| B | 40 | 7.3 | 1475 | 74 | 0.6 | 1.1 | YB90L-4 | 1.5 | |

| C | 34 | 6 | 1475 | 69 | 0.5 | 0.8 | YB90S-4 | 1.1 | |

| D | 26 | 5 | 1475 | 65 | 0.5 | 0.5 | YB80M2-4 | 0.75 | |

| 80-200 | A | 52 | 13.5 | 1475 | 74 | 0.8 | 2.6 | YB112M-4 | 4 |

| B | 47 | 12 | 1475 | 74 | 0.6 | 2.1 | YB100L2-4 | 3 | |

| C | 40 | 9.8 | 1475 | 71 | 0.6 | 1.5 | YB100L1-4 | 2.2 | |

| D | 34 | 7.7 | 1475 | 68 | 0.6 | 1 | YB100L1-4 | 2.2 | |

| 80-250 | A | 64 | 20 | 1475 | 72 | 1.3 | 4.8 | YB132M-4 | 7.5 |

| B | 60 | 19 | 1475 | 70 | 1.2 | 4.4 | YB132M-4 | 7.5 | |

| C | 52 | 14.5 | 1475 | 67 | 0.9 | 3.1 | YB132S-4 | 5.5 | |

| D | 16 | 11 | 1475 | 64 | 0.9 | 2.2 | YB132S-4 | 4 | |

| 80-315 | A | 70 | 33 | 1475 | 66.5 | 1 | 9.5 | YB160L-4 | 15 |

| B | 66 | 30 | 1475 | 65 | 0.9 | 8.3 | YB160M-4 | 11 | |

| C | 56 | 24 | 1475 | 62 | 0.7 | 5.9 | YB160M-4 | 11 | |

| D | 45 | 18 | 1475 | 57 | 0.7 | 3.9 | YB132M-4 | 7.5 | |

| 80-400 | A | 85 | 46 | 1475 | 58 | 0.8 | 18.4 | YB180L-4 | 22 |

| B | 80 | 42 | 1475 | 57 | 0.7 | 16.1 | YB180M-4 | 18.5 | |

| C | 65 | 33 | 1475 | 54 | 0.5 | 10.8 | YB160L-4 | 15 | |

| D | 53 | 25 | 1475 | 50 | 0.6 | 7.2 | YB160M-4 | 11 | |

| 80-450 | A | 103 | 60 | 1475 | 57 | 1.4 | 29.5 | YB225S-4 | 37 |

| B | 98 | 57 | 1475 | 56.5 | 1.3 | 26.5 | YB225S-4 | 37 | |

| C | 80 | 50 | 1475 | 56 | 1.3 | 19.4 | YB200L-4 | 30 | |

| D | 70 | 33 | 1475 | 54 | 1.3 | 11.6 | YB160L-4 | 15 | |

| 100-160 | A | 82 | 7.2 | 1475 | 79.5 | 1 | 2 | YB100L2-4 | 3 |

| B | 70 | 6.2 | 1475 | 77 | 1.1 | 1.5 | YB100L1-4 | 2.2 | |

| C | 55 | 5 | 1475 | 73 | 0.6 | 1 | YB90L-4 | 1.5 | |

| D | 45 | 4 | 1475 | 65 | 0.5 | 0.8 | YB90S-4 | 1.1 | |

| 100-200 | A | 97 | 12.5 | 1475 | 79.5 | 1 | 4.2 | YB132S-4 | 5.5 |

| B | 85 | 11.3 | 1475 | 77 | 0.8 | 3.4 | YB132S-4 | 5.5 | |

| C | 70 | 9.5 | 1475 | 73 | 0.8 | 2.5 | YB100L2-4 | 3 | |

| D | 60 | 7 | 1475 | 70 | 0.5 | 1.6 | YB100L1-4 | 2.2 | |

| 100-250 | A | 115 | 20 | 1475 | 79.5 | 1 | 7.9 | YB160M-4 | 11 |

| B | 110 | 18 | 1475 | 79 | 0.9 | 6.8 | YB160M-4 | 11 | |

| C | 100 | 14 | 1475 | 77.5 | 0.8 | 4.9 | YB132M-4 | 7.5 | |

| D | 90 | 10 | 1475 | 76 | 1 | 3.2 | YB132S-4 | 5.5 | |

| 100-315 | A | 125 | 31 | 1475 | 73 | 0.9 | 14 | YB180M-4 | 18.5 |

| B | 119 | 29 | 1475 | 72.5 | 0.8 | 13 | YB180M-4 | 18.5 | |

| C | 104 | 24 | 1475 | 71 | 0.7 | 9.6 | YB160L-4 | 15 | |

| D | 86 | 17.5 | 1475 | 65 | 0.6 | 6.3 | YB160M-4 | 11 | |

| 100-400 | A | 150 | 48 | 1475 | 70 | 1.4 | 28 | YB225S-4 | 37 |

| B | 145 | 44 | 1475 | 69 | 1.3 | 25.2 | YB200L-4 | 30 | |

| C | 130 | 36 | 1475 | 68 | 1.2 | 18.7 | YB180L-4 | 22 | |

| D | 115 | 26 | 1475 | 65 | 1.3 | 12.5 | YB180M-4 | 18.5 | |

| 100-450 | A | 167 | 63 | 1475 | 68 | 1.7 | 42.1 | YB250M-4 | 55 |

| B | 153 | 60 | 1475 | 68 | 1.5 | 36.8 | YB225M-4 | 45 | |

| C | 130 | 50 | 1475 | 66.5 | 1.6 | 26.6 | YB225S-4 | 37 | |

| D | 110 | 34 | 1475 | 65 | 2 | 15.7 | YB180L-4 | 22 | |

| 100-500 | A | 180 | 75 | 1475 | 70 | 1.5 | 52.5 | YB280S-4 | 75 |

| B | 150 | 71 | 1475 | 68 | 1 | 42.6 | YB250M-4 | 55 | |

| C | 130 | 56 | 1475 | 65 | 0.8 | 30.5 | YB225S-4 | 37 | |

| D | 100 | 45 | 1475 | 60 | 0.6 | 20.4 | YB200L-4 | 30 | |

| 150-200 | A | 160 | 11 | 1475 | 82 | 1.6 | 5.8 | YB132M-4 | 7.5 |

| B | 142 | 10 | 1475 | 80 | 1.3 | 4.8 | YB132S-4 | 5.5 | |

| C | 121 | 8 | 1475 | 75 | 1.3 | 3.5 | YB132S-4 | 5.5 | |

| D | 100 | 6.3 | 1475 | 70 | 1 | 2.5 | YB112M-4 | 4 | |

| 50-250 | A | 195 | 18.5 | 1475 | 80.5 | 1.3 | 12.2 | YB180M-4 | 18.5 |

| B | 180 | 16 | 1475 | 78 | 1.2 | 10.1 | YB160L-4 | 15 | |

| C | 160 | 11.5 | 1475 | 75 | 1.2 | 6.7 | YB160M-4 | 11 | |

| 150-315 | A | 220 | 32.5 | 1475 | 81 | 1.7 | 24 | YB200L-4 | 30 |

| B | 210 | 30 | 1475 | 80 | 1.56 | 21.4 | YB200L-4 | 30 | |

| C | 180 | 24 | 1475 | 75 | 1.3 | 15.7 | YB180L-4 | 22 | |

| D | 115 | 17 | 1475 | 70 | 1.2 | 7.6 | YB160L-4 | 15 | |

| 150-400 | A | 260 | 51 | 1475 | 77 | 1.8 | 47 | YB250M-4 | 55 |

| B | 250 | 48 | 1475 | 76 | 1.7 | 43 | YB250M-4 | 55 | |

| C | 225 | 38 | 1475 | 75 | 1.5 | 31 | YB225M-4 | 45 | |

| D | 200 | 28 | 1475 | 73 | 1.4 | 21 | YB200L-4 | 30 | |

| 150-450 | A | 275 | 63 | 1475 | 73 | 2 | 64.6 | YB280M-4 | 90 |

| B | 260 | 60 | 1475 | 73 | 1.8 | 58.2 | YB280S-4 | 75 | |

| C | 220 | 54 | 1475 | 72 | 1.5 | 44.9 | YB250M-4 | 55 | |

| D | 180 | 35 | 1475 | 69 | 1.5 | 86.1 | YB200L-4 | 30 | |

| 150-500 | A | 300 | 78 | 1475 | 74 | 2 | 86.1 | YB315S-4 | 110 |

| B | 280 | 73 | 1475 | 74 | 1.5 | 75.2 | YB280M-4 | 90 | |

| C | 235 | 60 | 1475 | 72 | 1.2 | 53.3 | YB180S-4 | 75 | |

| D | 200 | 45 | 1475 | 70 | 1 | 35 | YB225M-4 | 45 | |

| 150-560 | A | 340 | 104 | 1475 | 74.5 | 2.5 | 129.2 | YB315L1-4 | 160 |

| B | 300 | 100 | 72 | 2 | 113.4 | YB315M-4 | 132 | ||

| C | 260 | 80 | 71 | 2.5 | 79.7 | YB315S-4 | 110 | ||

| D | 220 | 60 | 67 | 2.1 | 53.6 | YB280S-4 | 75 | ||

| 150-630 | A | 360 | 115 | 63 | 2.3 | 179.9 | YB355m1-4 | 220 | |

| B | 340 | 105 | 63 | 2 | 154.3 | YB355S1-4 | 185 | ||

| C | 300 | 80 | 56.5 | 1.8 | 115.6 | YB315M1-4 | 132 | ||

| D | 260 | 50 | 50 | 2.5 | 70.8 | YB280M-4 | 90 | ||

| 200-250 | A | 305 | 17.5 | 83.5 | 2.56 | 17.4 | YB180L-4 | 22 | |

| B | 290 | 16 | 83 | 2 | 15.2 | YB180M-4 | 18.5 | ||

| C | 260 | 12 | 81 | 1.6 | 10.4 | YB160L-4 | 15 | ||

| D | 240 | 8 | 79 | 15 | 6.6 | YB160M-4 | 11 | ||

| 200-315 | A | 350 | 30 | 84.5 | 2 | 32.8 | YB225M-4 | 45 | |

| B | 340 | 29 | 83 | 2 | 32.4 | YB225M-4 | 45 | ||

| C | 300 | 22 | 80 | 1.7 | 22.5 | YB225S-4 | 37 | ||

| D | 250 | 15 | 77 | 1.3 | 13.3 | YB180L-4 | 22 | ||

| 200-400 | A | 426 | 50 | 81 | 3.3 | 71.6 | YB280M-4 | 90 | |

| B | 410 | 47 | 80 | 3 | 65.6 | YB280S-4 | 75 | ||

| C | 370 | 36.5 | 79 | 2.3 | 47.2 | YB250M-4 | 55 | ||

| D | 332 | 27 | 75 | 2.3 | 32.5 | YB225M-4 | 45 | ||

| 200-450 | A | 460 | 65 | 78 | 3 | YB315M-4 | 132 | ||

| B | 440 | 61 | 78 | 2.8 | 93.7 | YB315S-4 | 110 | ||

| C | 360 | 52 | 76 | 2.2 | 67.1 | YB280M-4 | 90 | ||

| D | 300 | 35 | 72 | 2.3 | 39.7 | YB280S-4 | 55 | ||

| 200-500 | A | 500 | 84 | 81 | 2.8 | 141.2 | YB315L1-4 | 160 | |

| B | 470 | 78 | 81 | 2.5 | 123.2 | YB315L1-4 | 160 | ||

| C | 400 | 64 | 78 | 2 | 89.3 | YB315S-4 | 110 | ||

| D | 300 | 52 | 72 | 1.8 | 59 | YB280S-4 | 75 | ||

| 200-560 | A | 545 | 105 | 79.5 | 3 | 195.9 | YB355M1-4 | 220 | |

| B | 500 | 100 | 78 | 2.4 | 174.5 | YB315L2-4 | 200 | ||

| C | 440 | 80 | 76 | 2 | 126.1 | YB315L1-4 | 160 | ||

| D | 300 | 67 | 72 | 1.7 | 76 | YB280M-4 | 90 | ||

| 200-630 | A | 580 | 132 | 77.5 | 3.3 | 268.9 | YB355L1-4 | 315 | |

| B | 550 | 125 | 77 | 2.3 | 243.1 | YB355L1-4 | 280 | ||

| C | 480 | 100 | 73 | 2.3 | 179 | YB315L2-4 | 200 | ||

| D | 370 | 76 | 70 | 2.3 | 109.4 | YB315M-4 | 132 | ||

| 250-315 | A | 545 | 27 | 86.5 | 2.9 | 46.3 | YB315M-4 | 55 | |

| B | 528 | 25 | 85 | 2.7 | 42.3 | YB250M-4 | 55 | ||

| C | 480 | 19 | 82 | 2.3 | 30.3 | YB250M-4 | 45 | ||

| D | 434 | 13 | 77 | 2 | 20 | YB225M-4 | 30 | ||

| 250-400 | A | 600 | 49 | 83.5 | 3.2 | 105.4 | YB315M-4 | 132 | |

| B | 630 | 46 | 83 | 3 | 95 | YB315S-4 | 110 | ||

| C | 565 | 36 | 82 | 2.3 | 68 | YB280M-4 | 90 | ||

| D | 500 | 24 | 78 | 2 | 42 | YB250M-4 | 55 | ||

| 250-500 | A | 800 | 86 | 83 | 5 | 217.8 | YB355M2-4 | 250 | |

| B | 750 | 78 | 82 | 4.5 | 194.2 | YB355M1-4 | 220 | ||

| C | 680 | 60 | 80 | 4 | 138.8 | YB315L1-4 | 160 | ||

| D | 558 | 45 | 76 | 4.2 | 89.9 | YB315S-4 | 110 | ||

| 250-560 | A | 860 | 1.6 | 82 | 4.1 | 302.6 | 355 | ||

| B | 830 | 98 | 82 | 4 | 270 | YB355L2-4 | 315 | ||

| C | 750 | 78 | 80 | 3.4 | 199.1 | YB355M1-4 | 220 | ||

| D | 600 | 62 | 76 | 2.6 | 133.2 | YB315L1-4 | 160 | ||

| 250-630 | A | 850 | 128 | 80.5 | 4.5 | 367.9 | 450 | ||

| B | 815 | 120 | 80.5 | 4 | 330.7 | 400 | |||

| C | 700 | 97 | 79 | 2.7 | 234 | YB315L1-4 | 280 | ||

| D | 550 | 75 | 76 | 1.5 | 147.8 | YB315L1-4 | 185 | ||

| 300-400 | A | 1050 | 48 | 87 | 5.7 | 158 | YB355S1-4 | 185 | |

| B | 1010 | 45 | 86 | 5.1 | 144 | YB355L-4 | 160 | ||

| C | 900 | 34 | 83 | 3.9 | 100 | YB315M-4 | 132 | ||

| D | 780 | 26 | 78 | 4.5 | 71 | YB280M-4 | 90 | ||

| 300-500 | A | 1230 | 78 | 88 | 4.7 | 296.8 | 355 | ||

| B | 1100 | 75 | 87 | 4 | 261.6 | YB355L2-4 | 315 | ||

| C | 1000 | 57 | 86 | 3.4 | 180.4 | YB315L2-4 | 200 | ||

| D | 850 | 43 | 80 | 3.8 | 124.4 | YB315L1-4 | 160 | ||

| 300-560 | A | 1350 | 104 | 87 | 5.1 | 439.3 | 500 | ||

| B | 1270 | 98 | 87 | 4.5 | 389.4 | 450 | |||

| C | 1100 | 80 | 84 | 3.5 | 285.2 | YB355L2-4 | 315 | ||

| D | 950 | 57 | 80 | 3.2 | 184.3 | YB355M1-4 | 220 | ||

| 400-500 | A | 1900 | 74 | 88 | 6.2 | 439.9 | 500 | ||

| B | 1800 | 70 | 88 | 5.8 | 389.8 | 450 | |||

| C | 1600 | 50 | 85 | 5 | 256.2 | YB355L1-4 | 280 | ||

| D | 1300 | 38 | 80 | 4.2 | 168.1 | YB355S1-4 | 185 | ||

| 400-560 | A | 2050 | 98 | 88 | 7.5 | 621.5 | 710 | ||

| B | 1900 | 92 | 87 | 6 | 546.9 | 630 | |||

| C | 1700 | 75 | 86 | 4.2 | 403.6 | 450 | |||

| D | 1300 | 58 | 81 | 3.1 | 253.4 | YB355L1-4 | 280 | ||

| 400-630 | A | 2400 | 125 | 88 | 8.6 | 928 | 1120 | ||

| B | 2200 | 120 | 87.5 | 6.6 | 821.3 | 900 | |||

| C | 2000 | 95 | 86 | 5 | 601.4 | 7100 | |||

| D | 1600 | 70 | 80 | 5.5 | 381.1 | 450 | |||

| 400-720 | A | 2750 | 168 | 88 | 11.3 | 1429.2 | 1600 | ||

| B | 2500 | 160 | 87 | 9.5 | 1251.6 | 1400 | |||

| C | 2300 | 130 | 85.5 | 8.3 | 952 | 1120 | |||

| D | 2100 | 105 | 82 | 10 | 732 | 800 | |||

Previous product:TCD no leakage petrochemical multistage magnetic pump

Next Product:TCA no leakage petrochemical magnetic pump