|

|

| TCF Non-leakage fluorine lining magnetic pump |

Selection of color |

||||||

|

||||||

|

|

| Model significance | TCF80-65-160 |

| T | Enterprise Code |

| C | Magnetic drive |

| F | Fluorine plastic material |

| 80 | Import caliber 80mm |

| 65 | Outlet aperture 65mm |

| 160 | Nominal diameter of the impeller 160mm |

一、Product Introduction:

Product overview:

Non-leakage fluorine lining magnetic pump (shorter form: fluorine lining magnetic pump) is application of modern magnetic principles, which is a new type pump using the magnetic transmission of permanent magnet to implement torque’s contactless transmission, that is, when electric motor drives outer rotor(i.e. outer magnetic steel) assembly rotating , under magnetic field, magnetic line of force pass through distance sleeve drive inner rotor(i.e. inner magnetic steel) assembly rotating synchronously with impeller. The flowing-passed components are all made of fluoroplastics, which allow delivery corrosive media of any concentration of acid, lye, oxidants. The distance sleeve is made of special material with high-intensity mechanical property, eliminating the phenomenon of magnetic eddy current existing in magnetic driven pumps. The purpose of pumping media without leaking is due to the media closed in still distance sleeve, which completely solve the problem of shaft seal leakage of mechanical pump. This new design Non-leakage anti-acid pump has many characteristics of full sealing, No leakage, No pollution, strong anti-acid and energy-efficient, its performance already reaches international standard, thus can replace the expensive imported chemical pump(special metallic or stainless steel).

Design features:

1. TCF non-leakage fluorine lining magnetic pump is a new type industrial pump of full sealing, no leakage, no pollution and strong anti-acid, which is designed voluntarily by ourselves.

2. The whole pump body be sintered and pressed of cast-iron with fluorine lining (PTFE, FEP, PEA). The flowing-passed components like pump body, impeller, pump cover are entirely pressed and sintered of fluoroplastic (PTFE, FEP, PFA) covering metal insert.

3. Fluoroplastic (PTFE, FEP and PFA) is the most superior anti-corrosive materials in the nowadays world, be free from corrosive media of any concentration of acid, lye, oxidants, etc.

4. New type permanent magnet with good magnetism, high temperature resistant and No demagnetization is selected.

5. Shaft sleeve, sleeve bearings be made of graphite and PTFE material with good characteristic of superior wear resistance and high temperature resistance, lubrication groove setting, which guarantee the pump’s working life.

6. Enclosed static seal completely solves the problem of dielectric leakage.

8. Direct coupling pull back design, No need to dismount pipe, easier maintenance.

9. Horizontal mount, compact structure, low voice, small vibration, small occupation and stable operation.

10. No contact and no friction, change coupling transmission to synchronic pulling. Power consumption of small, high efficiency, and has a damping effect, reducing vibration on the pump motor and pump in the effects of cavitations vibration when the impact of the motor.

Application:

Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery media of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range:

Design pressure: 1.6Mpa

Flow: 2-200m3/h

Head: 12-125m

Power: 1.1-55kw

Applicable temperature: -20~120℃, can be up to 180℃ if using new material.

The optional accessories: preventive idling running device, monitoring of leakage device, monitoring of temperature device

Notes: Pls indicate during ordering if the proportion of delivering media is larger than 1.3mg/cm3. No idle running. No delivering media with particle or crystalline.

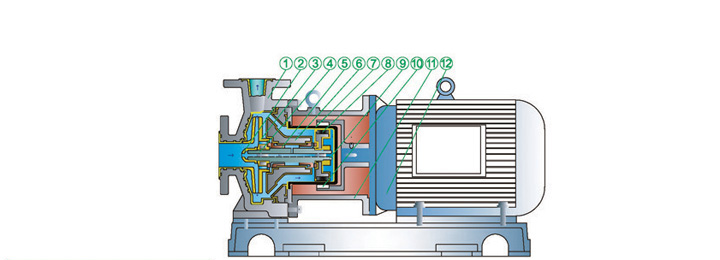

二、Structure drawing:

三、Performance Curve:

四、Performance data sheet:

| model |

Rotating speed |

flow m3/h |

Head m |

effectiveness % |

NPSH m |

Import X export mm |

power kw |

weight kg |

| TCF25-20-125 | 2900 | 1.5 | 22 | 18 | 2.5 | 25×20 | 1.1 | 27 |

| 2 | 20 | 20 | 2.5 | |||||

| 3.2 | 18.5 | 24 | 3 | |||||

| TCF25-20-160 | 2900 | 1.5 | 34.3 | 19 | 2.5 | 25×20 | 1.5 | 36 |

| 2 | 32 | 22 | 2.5 | |||||

| 3.2 | 29.6 | 25 | 3 | |||||

| TCF25-20-200A | 2900 | 1.5 | 42 | 28 | 2.5 | 25×20 | 3 | 51 |

| 2 | 40 | 32 | 2.5 | |||||

| 3.2 | 38 | 30 | 3 | |||||

| TCF25-20-200 | 2900 | 1.5 | 52.5 | 18 | 2.5 | 25×20 | 3 | 51 |

| 2 | 50 | 20 | 2.5 | |||||

| 3.2 | 48 | 22 | 3 | |||||

| TCF25-20-250A | 2900 | 1.5 | 62 | 26 | 2.5 | 25×20 | 5.5 | 63 |

| 2 | 60 | 30 | 2.5 | |||||

| 3.2 | 58 | 28 | 3 | |||||

| TCF25-20-250B | 2900 | 1.5 | 72 | 26 | 2.5 | 25×20 | 7.5 | 63 |

| 2 | 70 | 30 | 2.5 | |||||

| 3.2 | 68 | 28 | 3 | |||||

| TCF25-20-250 | 2900 | 1.5 | 82 | 12 | 2.5 | 25×20 | 7.5 | 63 |

| 2 | 80 | 18 | 2.5 | |||||

| 3.2 | 78.5 | 26 | 3 | |||||

| TCF32-20-125 | 2900 | 2 | 22 | 20.5 | 2.5 | 32×20 | 1.5 | 30 |

| 3.2 | 20 | 20 | 2.5 | |||||

| 5.5 | 18.5 | 18 | 3 | |||||

| TCF32-20-160 | 2900 | 2 | 34.3 | 20.5 | 2.5 | 32×20 | 2.2 | 35 |

| 3.2 | 32 | 20 | 2.5 | |||||

| 5.5 | 29.6 | 18 | 3 | |||||

| TCF32-20-200A | 2900 | 2 | 42 | 25 | 2.5 | 32×20 | 4 | 61 |

| 3.2 | 40 | 24 | 2.5 | |||||

| 5.5 | 38 | 21.5 | 3 | |||||

| TCF32-20-200 | 2900 | 2 | 52.5 | 32 | 2.5 | 32×20 | 4 | 61 |

| 3.2 | 50 | 36 | 2.5 | |||||

| 5.5 | 48 | 34 | 3 | |||||

| TCF32-20-250A | 2900 | 2 | 62 | 22 | 2.5 | 32×20 | 7.5 | 71 |

| 3.2 | 60 | 26 | 2.5 | |||||

| 5.5 | 58 | 28.5 | 3 | |||||

| TCF32-20-250B | 2900 | 2 | 72 | 26 | 2.5 | 32×20 | 7.5 | 75 |

| 3.2 | 70 | 30 | 2.5 | |||||

| 5.5 | 68 | 28 | 3 | |||||

| TCF32-20-250 | 2900 | 2 | 82 | 26 | 2.5 | 32×20 | 7.5 | 75 |

| 3.2 | 80 | 30 | 2.5 | |||||

| 5.5 | 78.5 | 28 | 3 | |||||

| TCF40-25-125 | 2900 | 4.4 | 22 | 16 | 2.5 | 40×25 | 1.5 | 35 |

| 6.3 | 20 | 20 | 2.5 | |||||

| 8.3 | 18.5 | 23 | 3 | |||||

| TCF40-25-160 | 2900 | 4.4 | 34.3 | 30 | 2.5 | 40×25 | 3 | 40 |

| 6.3 | 32 | 31 | 2.5 | |||||

| 8.3 | 29.6 | 32 | 3 | |||||

| TCF40-25-200A | 2900 | 4.4 | 42 | 30 | 2.5 | 40×25 | 4 | 66 |

| 6.3 | 40 | 31 | 2.5 | |||||

| 8.3 | 38 | 32 | 3 | |||||

| TCF40-25-200 | 2900 | 4.4 | 52.5 | 26 | 2.5 | 40×25 | 5.5 | 66 |

| 6.3 | 50 | 33 | 2.5 | |||||

| 8.3 | 48 | 32 | 3 | |||||

| TCF40-25-250A | 2900 | 4.4 | 62 | 20 | 2.5 | 40×25 | 11 | 95 |

| 6.3 | 60 | 23 | 2.5 | |||||

| 8.3 | 58 | 30 | 3 | |||||

| TCF40-25-250B | 2900 | 4.4 | 72 | 24 | 2.5 | 40×25 | 11 | 95 |

| 6.3 | 70 | 28 | 2.5 | |||||

| 8.3 | 68 | 28 | 3 | |||||

| TCF40-25-250 | 2900 | 4.4 | 82 | 24 | 2.5 | 40×25 | 11 | 95 |

| 6.3 | 80 | 28 | 2.5 | |||||

| 8.3 | 78.5 | 28 | 3 | |||||

| TCF50-32-125 | 2900 | 7.5 | 22 | 43 | 2 | 50×32 | 2.2 | 44 |

| 12.5 | 20 | 51 | 2 | |||||

| 15 | 18.5 | 49 | 2.5 | |||||

| TCF50-32-160 | 2900 | 7.5 | 34.3 | 35 | 2 | 50×32 | 3 | 61 |

| 12.5 | 32 | 47 | 2 | |||||

| 15 | 29.6 | 47 | 2.5 | |||||

| TCF50-32-200A | 2900 | 7.5 | 42 | 28 | 2 | 50×32 | 7.5 | 113 |

| 12.5 | 40 | 39 | 2 | |||||

| 15 | 38 | 43 | 2.5 | |||||

| TCF50-32-200 | 2900 | 7.5 | 52.5 | 28 | 2 | 50×32 | 7.5 | 113 |

| 12.5 | 50 | 40 | 2 | |||||

| 15 | 48 | 48 | 2.5 | |||||

| TCF50-32-250A | 2900 | 7.5 | 62 | 23 | 2 | 50×32 | 7.5 | 180 |

| 12.5 | 60 | 33 | 2 | |||||

| 15 | 58 | 36.5 | 2.5 | |||||

| TCF50-32-250B | 2900 | 7.5 | 72 | 23 | 2 | 50×32 | 11 | 180 |

| 12.5 | 70 | 33 | 2 | |||||

| 15 | 68 | 36.5 | 2.5 | |||||

| TCF50-32-250 | 2900 | 7.5 | 82 | 23 | 2 | 50×32 | 11 | 180 |

| 12.5 | 80 | 33 | 2 | |||||

| 15 | 78.5 | 36.5 | 2.5 | |||||

| TCF65-50-125 | 2900 | 15 | 21.8 | 46 | 2 | 65×50 | 3 | 80 |

| 25 | 20 | 56 | 2 | |||||

| 30 | 18.5 | 65 | 2.5 | |||||

| TCF65-50-160 | 2900 | 15 | 35 | 46 | 2 | 65×50 | 5.5 | 97 |

| 25 | 32 | 56 | 2 | |||||

| 30 | 30 | 65 | 2.5 | |||||

| TCF65-40-200A | 2900 | 15 | 42 | 41 | 2 | 65×40 | 11 | 130 |

| 25 | 40 | 52 | 2 | |||||

| 30 | 38 | 53.5 | 2.5 | |||||

| TCF65-40-200 | 2900 | 15 | 53 | 34 | 2 | 65×40 | 11 | 120 |

| 25 | 50 | 46 | 2 | |||||

| 30 | 47 | 50 | 2.5 | |||||

| TCF65-40-250A | 2900 | 15 | 62 | 28 | 2 | 65×40 | 15 | 203 |

| 25 | 60 | 39 | 2 | |||||

| 30 | 58 | 42.5 | 2.5 | |||||

| TCF65-40-250B | 2900 | 15 | 72 | 28 | 2 | 65×40 | 18.5 | 203 |

| 25 | 70 | 39 | 2 | |||||

| 30 | 68 | 42.5 | 2.5 | |||||

| TCF65-40-250 | 2900 | 15 | 82 | 33 | 2 | 65×40 | 18.5 | 203 |

| 25 | 80 | 48 | 2 | |||||

| 30 | 78 | 50 | 2.5 | |||||

| TCF65-40-315A | 2900 | 15 | 105 | 28 | 2.5 | 65×40 | 30 | 345 |

| 25 | 100 | 39 | 2.5 | |||||

| 30 | 98 | 42.5 | 3 | |||||

| TCF65-40-315 | 2900 | 15 | 127 | 28 | 2.5 | 65×40 | 30 | 345 |

| 25 | 125 | 39 | 2.5 | |||||

| 30 | 123 | 42.5 | 3 | |||||

| TCF80-65-125 | 2900 | 30 | 22.5 | 52 | 3 | 80×65 | 5.5 | 125 |

| 50 | 20 | 65 | 3 | |||||

| 60 | 18 | 70 | 3.5 | |||||

| TCF80-65-160 | 2900 | 30 | 36 | 60 | 2.5 | 80×65 | 11 | 137 |

| 50 | 32 | 64 | 2.5 | |||||

| 60 | 29 | 53 | 3 | |||||

| TCF80-50-200A | 2900 | 30 | 42 | 53 | 2.5 | 80×50 | 15 | 207 |

| 50 | 40 | 63 | 2.5 | |||||

| 60 | 38 | 62 | 3 | |||||

| TCF80-50-200 | 2900 | 30 | 53 | 53 | 2.5 | 80×50 | 15 | 207 |

| 50 | 50 | 63 | 2.5 | |||||

| 60 | 47 | 55 | 3 | |||||

| TCF80-50-250A | 2900 | 30 | 62 | 44 | 2.5 | 80×50 | 22 | 275 |

| 50 | 60 | 57 | 2.5 | |||||

| 60 | 58 | 59 | 3 | |||||

| TCF80-50-250B | 2900 | 30 | 72 | 44 | 2.5 | 80×50 | 30 | 275 |

| 50 | 70 | 57 | 2.5 | |||||

| 60 | 68 | 59 | 3 | |||||

| TCF80-50-250 | 2900 | 30 | 84 | 48 | 2.5 | 80×50 | 30 | 275 |

| 50 | 80 | 56 | 2.5 | |||||

| 60 | 75 | 50 | 3 | |||||

| TCF80-50-315A | 2900 | 30 | 105 | 39 | 2.5 | 80×50 | 37 | 390 |

| 50 | 100 | 51 | 2.5 | |||||

| 60 | 98 | 52.5 | 3 | |||||

| TCF80-50-315 | 2900 | 30 | 128 | 39 | 2.5 | 80×50 | 37 | 390 |

| 50 | 125 | 51 | 2.5 | |||||

| 60 | 123 | 52.5 | 3 | |||||

| TCF100-80-125 | 2900 | 60 | 24 | 64 | 4 | 100×80 | 11 | 193 |

| 100 | 20 | 65 | 4.5 | |||||

| 120 | 16.5 | 63 | 5 | |||||

| TCF100-80-160 | 2900 | 60 | 36 | 60 | 3.5 | 100×80 | 15 | 214 |

| 100 | 32 | 70 | 4 | |||||

| 120 | 28 | 65 | 5 | |||||

| TCF100-65-200A | 2900 | 60 | 42 | 63 | 3 | 100×65 | 18.5 | 213 |

| 100 | 40 | 72 | 3.6 | |||||

| 120 | 38 | 71 | 4.8 | |||||

| TCF100-65-200 | 2900 | 60 | 54 | 63 | 3 | 100×65 | 22 | 246 |

| 100 | 50 | 68 | 3.6 | |||||

| 120 | 47 | 56 | 4.8 | |||||

| TCF100-65-250A | 2900 | 60 | 62 | 57 | 3.5 | 100×65 | 30 | 372 |

| 100 | 60 | 68 | 3.8 | |||||

| 120 | 58 | 67 | 4.8 | |||||

| TCF100-65-250B | 2900 | 60 | 72 | 57 | 3.5 | 100×65 | 37 | 372 |

| 100 | 70 | 68 | 3.8 | |||||

| 120 | 68 | 67 | 4.8 | |||||

| TCF100-65-250 | 2900 | 60 | 87 | 60 | 3.5 | 100×65 | 37 | 372 |

| 100 | 80 | 68 | 3.8 | |||||

| 120 | 74.5 | 67 | 4.8 | |||||

| TCF100-65-315A | 2900 | 60 | 105 | 48 | 3 | 100×65 | 75 | 685 |

| 100 | 100 | 62 | 3.6 | |||||

| 120 | 98 | 64 | 4.2 | |||||

| TCF100-65-315 | 2900 | 60 | 133 | 63 | 3 | 100×65 | 75 | 685 |

| 100 | 125 | 65 | 3.6 | |||||

| 120 | 118 | 62 | 4.2 | |||||

| TCF125-100-200 | 2900 | 120 | 57.5 | 63 | 4.5 | 125×100 | 45 | 378 |

| 200 | 50 | 75 | 4.5 | |||||

| 240 | 44.5 | 74 | 5 | |||||

| TCF125-100-250A | 2900 | 120 | 62 | 63 | 3.8 | 125×100 | 55 | 447 |

| 200 | 60 | 75 | 4.2 | |||||

| 240 | 58 | 74 | 5 | |||||

| TCF125-100-250B | 2900 | 120 | 72 | 57 | 3.8 | 125×100 | 75 | 447 |

| 200 | 70 | 68 | 4.2 | |||||

| 240 | 68 | 67 | 5 | |||||

| TCF125-100-250 | 2900 | 120 | 87 | 57 | 3.8 | 125×100 | 75 | 447 |

| 200 | 80 | 68 | 4.2 | |||||

| 240 | 72 | 67 | 5 |

Previous product:TCGB Non-leakage magnetic heat pump

Next Product:暂无!