|

|

| TLF fluorine lined pipeline centrifugal pump |

Selection of color |

||||||

|

||||||

| Meaning | TLF50-32 |

| T | Code of enterprise |

| L | Vertical |

| F | Fluoroplastic |

| 50 | The inlet dia is 50mm |

| 32 | Nominal dia of impeller is 125mm |

一、Product Introduction:

Product overview:

Lining fluorine pipeline centrifugal pump is according to the pipeline centrifugal pump with non metal pump design and manufacturing process, suitable for long-term delivery of any of the concentration of strong acid, alkali, salt, strong oxidizing agents and other corrosive medium, the flow components made of all plastic alloy (PTFE, FEP), set a variety of plastic material pump has the advantages, with resistant, corrosion resistance, good abrasion resistance, high mechanical strength, aging, no toxin decomposition characteristics. The import and export of the pump are strengthened by steel casting, so as to enhance the pressure resistance of the pump. The pump has the advantages of corrosion resistance, abrasion resistance, high temperature resistance, non oxidation, high mechanical strength, stable operation, advanced structure, reliable sealing performance, convenient disassembly and maintenance, long service life, etc..

Features:

1.TLF fluorine lined pipeline centrifugal pump is designed according to the tech of pipeline centrifugal pump and nonmetal pump, which has features of anti-corrosion, anti-high temperature, anti-aging, high mechanical strength and energy-efficient.

2.Pump body be made of metal housing with FEP, PTFE or PFA lining, the flowing-passed components like pump body, impeller, pump cover are entirely pressed and sintered of fluoroplastic (PTFE, FEP, PFA) covering metal insert.

3.The shaft seal is sealed mechanically by external bellow, can be adjusted without dismounting; the optional grinding sealing surface: silicon carbide, PLSC, ceramic, PTFE, cemented carbide, etc, to make sure the demand of delivering all kinds of medium and the working life of shaft seal.

4.No need of independent lubrication and cooling, reducing energy consumption. Direct coupling pull back design, no need to dismount pipe, easier maintenance.

5.Vertical mount, compact structure, low voice, small vibration, small occupation and stable operation.

Application:Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery strong corrosive medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range:Design pressure:1.6Mpa、Flow:2-100m3/h、Head:12-80m、Power:1.1-90kw

Applicable temperature:-20~120℃,can be up to 180℃ if using new type material.

NOTES: Please indicate during ordering if the proportion of medium is largger than 1.3mg/cm3.No idling running. No delivering medium with particles or crystalline.

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 1.pump body | Ht200/ lined F46 | 4.pump cover | HT200/lined F46 | 7.dynamic ring | SSIC/hard alloy |

| 2.impeller | fluoroplastic alloy | 5.static ring | SSIC/hard alloy | 8.shaft |

45# |

| 3.gasket | fluorubber | 6.seal gland | 304/316/316L | 9.connection |

HT200 |

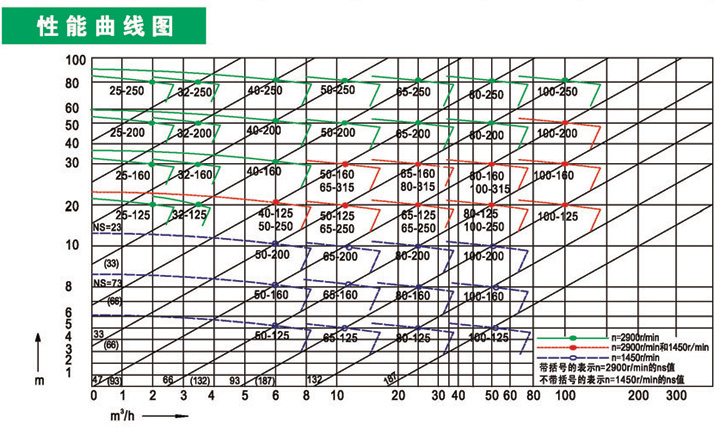

三、Performance Curve:

四、Performance data sheet:

| model | Rotating speed |

flow m3/h |

Head m |

effectiveness % |

NPSH m |

Inlet×Outlet mm |

power kw |

weight kg |

| TLF25-125 | 2900 | 1.5 | 22 | 28 | 2.5 | 25×25 | 1.1 | 28 |

| 2 | 20 | 36 | 2.5 | |||||

| 3.2 | 18.5 | 34 | 3 | |||||

| 1450 | 0.75 | 5.4 | 18 | 2.5 | 0.55 | 20 | ||

| 1 | 5 | 22 | 2.5 | |||||

| 1.6 | 4.6 | 28 | 3 | |||||

| TLF25-160 | 2900 | 1.5 | 34.3 | 24 | 2.5 | 25×25 | 1.5 | 39 |

| 2 | 32 | 32 | 2.5 | |||||

| 3.2 | 29.6 | 33 | 3 | |||||

| 1450 | 0.75 | 8.5 | 17 | 2.5 | 0.55 | 30 | ||

| 1 | 8 | 20 | 2.5 | |||||

| 1.6 | 7.5 | 26 | 3 | |||||

| TLF25-200 | 2900 | 1.5 | 52.5 | 28 | 2.5 | 25×25 | 7.5 | 41 |

| 2 | 50 | 32 | 2.5 | |||||

| 3.2 | 48 | 30 | 3 | |||||

| 1450 | 0.75 | 13.1 | 15 | 2.5 | 2.2 | 21 | ||

| 1 | 12.5 | 18 | 2.5 | |||||

| 1.6 | 12 | 24 | 3 | |||||

| TLF25-250 | 2900 | 1.5 | 82 | 26 | 2.5 | 25×25 | 11 | 53 |

| 2 | 80 | 30 | 2.5 | |||||

| 3.2 | 78.5 | 28 | 3 | |||||

| 1450 | 0.75 | 20.5 | 15 | 2.5 | 3 | 43 | ||

| 1 | 20 | 18 | 2.5 | |||||

| 1.6 | 19.5 | 24 | 3 | |||||

| TLF32-125 | 2900 | 2 | 22 | 40 | 2.5 | 32×32 | 2.2 | 28 |

| 3.2 | 20 | 44 | 2.5 | |||||

| 5.5 | 18.5 | 42 | 3 | |||||

| 1450 | 1 | 5.4 | 32 | 2.5 | 0.55 | 20 | ||

| 1.6 | 5 | 36 | 2.5 | |||||

| 2.75 | 4.6 | 34 | 3 | |||||

| TLF32-160 | 2900 | 2 | 34.3 | 34 | 2.5 | 32×32 | 3 | 26 |

| 3.2 | 32 | 40 | 2.5 | |||||

| 5.5 | 29.6 | 42 | 3 | |||||

| 1450 | 1 | 8.5 | 24 | 2.5 | 0.55 | 22 | ||

| 1.6 | 8 | 32 | 2.5 | |||||

| 2.75 | 7.5 | 30 | 3 | |||||

| TLF32-200 | 2900 | 2 | 52.5 | 32 | 2.5 | 32×32 | 7.5 | 30 |

| 3.2 | 50 | 36 | 2.5 | |||||

| 5.5 | 48 | 34 | 3 | |||||

| 1450 | 1 | 13.1 | 25 | 2.5 | 0.55 | 25 | ||

| 1.6 | 12.5 | 28 | 2.5 | |||||

| 2.75 | 12 | 26 | 3 | |||||

| TLF32-250 | 2900 | 2 | 82 | 26 | 2.5 | 32×32 | 18.5 | 65 |

| 3.2 | 80 | 30 | 2.5 | |||||

| 5.5 | 78.5 | 28 | 3 | |||||

| 1450 | 1 | 20.5 | 15 | 2.5 | 0.75 | 30 | ||

| 1.6 | 20 | 18 | 2.5 | |||||

| 2.75 | 19.5 | 24 | 3 | |||||

| TLF40-125 | 2900 | 8 | 20 | 31 | 2.5 | 40×40 | 1.5 | 50 |

| 6.3 | 20 | 30 | 2.5 | |||||

| 10 | 18.5 | 32 | 2.5 | |||||

| 1450 | 2.2 | 5.4 | 36 | 2.5 | 0.55 | 19 | ||

| 3.2 | 5 | 40 | 2.5 | |||||

| 4.2 | 4.6 | 38 | 3 | |||||

| TLF40-160 | 2900 | 8 | 32 | 31 | 3.5 | 40×40 | 3 | 82 |

| 6.3 | 32 | 30 | 3.5 | |||||

| 10 | 30 | 32 | 3.5 | |||||

| 1450 | 2.2 | 8.5 | 31 | 2.5 | 0.37 | 38 | ||

| 3.2 | 8 | 35 | 2.5 | |||||

| 4.2 | 7.5 | 33 | 3 | |||||

| TLF40-200 | 2900 | 4.4 | 52.5 | 26 | 2.5 | 40×40 | 5.5 | 74 |

| 6.3 | 50 | 33 | 2.5 | |||||

| 8.3 | 48 | 32 | 3 | |||||

| 1450 | 2.2 | 13.1 | 25 | 2.5 | 0.55 | 52 | ||

| 3.2 | 12.5 | 28 | 2.5 | |||||

| 4.2 | 12 | 26 | 3 | |||||

| TLF40-250 | 2900 | 4.4 | 82 | 24 | 2.5 | 40×40 | 11 | 105 |

| 6.3 | 80 | 28 | 2.5 | |||||

| 8.3 | 78.5 | 28 | 3 | |||||

| 1450 | 2.2 | 20.5 | 20 | 2.5 | 1.1 | 52 | ||

| 3.2 | 20 | 24 | 2.5 | |||||

| 4.2 | 19.5 | 22 | 3 | |||||

| TLF50-125 | 2900 | 7.5 | 22 | 43 | 2 | 50×50 | 2.2 | 33 |

| 12.5 | 20 | 51 | 2 | |||||

| 15 | 18.5 | 49 | 2.5 | |||||

| 1450 | 3.75 | 5.4 | 36 | 2 | 0.55 | |||

| 6.3 | 5 | 45 | 2 | |||||

| 7.5 | 4.6 | 44 | 2.5 | |||||

| TLF50-160 | 2900 | 7.5 | 32 | 40 | 3.5 | 50×50 | 4 | 40 |

| 12.5 | 30 | 45 | 3.5 | |||||

| 15 | 30 | 42 | 3.5 | |||||

| 1450 | 3.72 | 8.5 | 29 | 2 | 0.55 | |||

| 6.3 | 8 | 40 | 2 | |||||

| 7.5 | 7.5 | 43 | 2.5 | |||||

| TLF50-200 | 2900 | 7.5 | 52.5 | 28 | 2 | 50×50 | 7.5 | 46 |

| 12.5 | 50 | 39 | 2 | |||||

| 15 | 48 | 43 | 2.5 | |||||

| 1450 | 3.7 | 13.1 | 23 | 2 | 1.1 | |||

| 6.3 | 12.5 | 33 | 2 | |||||

| 7.5 | 12 | 36 | 2.5 | |||||

| TLF50-250 | 2900 | 7.5 | 82 | 23 | 2 | 50×50 | 11 | 80 |

| 12.5 | 80 | 33 | 2 | |||||

| 15 | 78.5 | 36.5 | 2.5 | |||||

| 1450 | 3.75 | 20.5 | 17 | 2 | 1.5 | |||

| 6.3 | 20 | 27 | 2 | |||||

| 7.5 | 19.5 | 31 | 2.5 | |||||

| TLF65-125 | 2900 | 15 | 22 | 47 | 2 | 65×65 | 3 | 83 |

| 25 | 20 | 52 | 2 | |||||

| 35 | 16 | 53 | 2.5 | |||||

| 1450 | 7.5 | 5.35 | 44 | 2 | 0.55 | |||

| 12.5 | 5 | 57 | 2 | |||||

| 15 | 4.7 | 59 | 2.5 | |||||

| TLF65-160 | 2900 | 15 | 35 | 44 | 2 | 65×65 | 5.5 | 40 |

| 25 | 32 | 57 | 2 | |||||

| 30 | 30 | 59 | 2.5 | |||||

| 1450 | 7.5 | 8.8 | 39 | 2 | 1.1 | |||

| 12.5 | 8 | 51 | 2 | |||||

| 15 | 7.2 | 52.5 | 2.5 | |||||

| TLF65-200 | 2900 | 15 | 53 | 41 | 2 | 65×65 | 11 | 49 |

| 25 | 50 | 52 | 2 | |||||

| 30 | 47 | 53.5 | 2.5 | |||||

| 1450 | 7.5 | 13.2 | 35 | 2 | 1.5 | |||

| 12.5 | 12.5 | 46 | 2 | |||||

| 15 | 11.8 | 47.5 | 2.5 | |||||

| TLF65-250 | 2900 | 15 | 82 | 34 | 2 | 65×65 | 18.5 | 87 |

| 25 | 80 | 46 | 2 | |||||

| 30 | 78 | 50 | 2.5 | |||||

| 1450 | 7.5 | 21 | 28 | 2 | 3 | |||

| 12.5 | 20 | 39 | 2 | |||||

| 15 | 19.4 | 43 | 2.5 | |||||

| TLF65-315 | 2900 | 15 | 127 | 28 | 2.5 | 65×65 | 30 | 119 |

| 25 | 125 | 39 | 2.5 | |||||

| 30 | 123 | 42.5 | 3 | |||||

| 1450 | 7.5 | 32.3 | 22 | 2.5 | 5.5 | |||

| 12.5 | 32 | 33 | 2.5 | |||||

| 15 | 31.7 | 37 | 3 | |||||

| TLF80-125 | 2900 | 30 | 22.5 | 53 | 3 | 80×80 | 5.5 | 42 |

| 50 | 20 | 63 | 3 | |||||

| 60 | 18 | 52 | 3.5 | |||||

| 1450 | 15 | 5.6 | 44 | 2.5 | 1.1 | |||

| 25 | 5 | 57 | 2.5 | |||||

| 30 | 4.5 | 58 | 3 | |||||

| TLF80-160 | 2900 | 30 | 36 | 57 | 2.5 | 80×80 | 11 | 44 |

| 50 | 32 | 67 | 2.5 | |||||

| 60 | 29 | 65 | 3 | |||||

| 1450 | 15 | 9 | 50 | 2.5 | 1.5 | |||

| 25 | 8 | 62 | 2.5 | |||||

| 30 | 7.2 | 62 | 3 | |||||

| TLF80-200 | 2900 | 30 | 53 | 53 | 2.5 | 80×80 | 15 | 51 |

| 50 | 50 | 63 | 2.5 | |||||

| 60 | 47 | 62 | 3 | |||||

| 1450 | 15 | 13.2 | 44 | 2.5 | 2.2 | |||

| 25 | 12.5 | 57 | 2.5 | |||||

| 30 | 11.8 | 58 | 3 | |||||

| TLF80-250 | 2900 | 30 | 84 | 44 | 2.5 | 80×80 | 30 | 81 |

| 50 | 80 | 57 | 2.5 | |||||

| 60 | 75 | 59 | 3 | |||||

| 1450 | 15 | 21 | 39 | 2.5 | 5.5 | |||

| 25 | 20 | 51 | 2.5 | |||||

| 30 | 18.8 | 52.5 | 3 | |||||

| TLF80-315 | 2900 | 30 | 128 | 39 | 2.5 | 80×80 | 37 | 121 |

| 50 | 125 | 51 | 2.5 | |||||

| 60 | 123 | 52.5 | 3 | |||||

| 1450 | 15 | 32.5 | 35 | 2.5 | 7.5 | |||

| 25 | 32 | 46 | 2.5 | |||||

| 30 | 31.5 | 47.5 | 3 | |||||

| TLF100-125 | 2900 | 60 | 24 | 64 | 4 | 100×100 | 11 | 43 |

| 100 | 20 | 73 | 4.5 | |||||

| 120 | 16.5 | 63 | 5 | |||||

| 1450 | 30 | 6 | 60 | 2.5 | 1.5 | |||

| 50 | 5 | 68 | 2.5 | |||||

| 60 | 4 | 63 | 3 | |||||

| TLF100-160 | 2900 | 60 | 36 | 60 | 3.5 | 100×100 | 15 | 63 |

| 100 | 32 | 73 | 4 | |||||

| 120 | 28 | 73 | 5 | |||||

| 1450 | 30 | 9.2 | 58 | 2 | 2.2 | |||

| 50 | 8 | 69 | 2.5 | |||||

| 60 | 6.8 | 68 | 3.5 | |||||

| TLF100-200 | 2900 | 60 | 54 | 63 | 3 | 100×100 | 30 | 77 |

| 100 | 50 | 72 | 3.6 | |||||

| 120 | 47 | 71 | 4.8 | |||||

| 1450 | 30 | 13.5 | 60 | 2 | 5.5 | |||

| 50 | 12.5 | 68 | 2 | |||||

| 60 | 11.8 | 63 | 2.5 | |||||

| TLF100-250 | 2900 | 60 | 87 | 57 | 3.5 | 100×100 | 45 | 92 |

| 100 | 80 | 68 | 3.8 | |||||

| 120 | 74.5 | 67 | 4.8 | |||||

| 1450 | 30 | 21.3 | 50 | 2 | 7.5 | |||

| 50 | 20 | 63 | 2 | |||||

| 60 | 19 | 64 | 2.5 | |||||

| TLF100-315 | 2900 | 60 | 132 | 57 | 3.5 | 100×100 | 75 | 165 |

| 100 | 125 | 68 | 3.8 | |||||

| 120 | 119 | 67 | 4.8 | |||||

| 1450 | 30 | 33.5 | 44 | 2 | 11 | |||

| 50 | 32 | 58 | 2 | |||||

| 60 | 30.5 | 60 | 2.5 |

五、Product real map:

![]()

Previous product:TSF fluorine alloy centrifugal pump

Next Product:TCQ no leakage magnetic pump