|

|

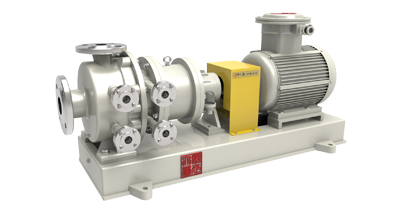

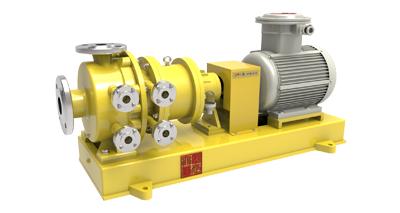

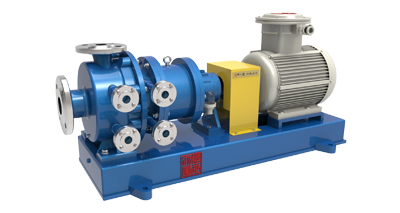

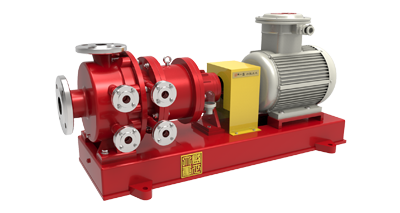

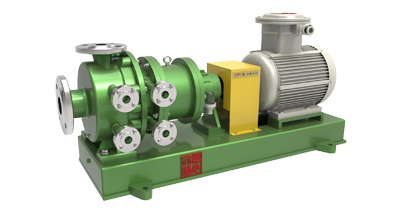

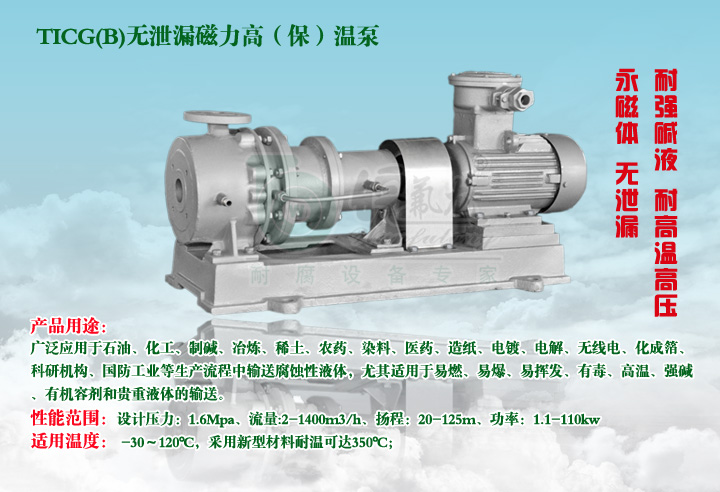

| TICB(G) no leakage heating (high-temperature) magnetic pump |

Selection of color |

||||||

|

||||||

| Model significance | TICG(B)80-65-160 |

| T | Enterprise Code |

| I | International standard chemical centrifugal pump |

| C | Magnetic drive |

| G | High-temperature type |

| B | Heating type |

| 80 | Import caliber80mm |

| 65 | Outlet aperture65mm |

| 160 | Nominal diameter of the impeller 160mm |

一、Product Introduction

FEATURES:

1.TICB(G) no leakage heating(high-temperature) magnetic pump is a new type industrial pump with characteristics of full sealing, no leakage, no pollution and heating(high-temperature), which is designed voluntarily by ourselves according to international standards of IS02858/GB5662/DIN24256. Its technical index and performance has already reached domestic and international advanced level of similar products.

2.1 The pump body and cover of magnetic high-temperature pump have two-ply cooling equipment (No cooling equipment in air-cooled pump), be allowed use water or nitrogen to cool medium in high-temperature pump, ensures medium keep cool in pump body.

2.2. Two-ply heat retaining equipment be settled on pump body and pump cover, which allow use steam to heat medium in pump body, ensure medium won’t condense, crystallize or gasify.

3.New type permanent magnet with good magnetism, high temperature resistant and No demagnetization is selected.

4.Shaft sleeve, slide bearing are made of graphite and PTFE material with good characteristic of superior wear resistance and high temperature resistance, lubrication groove setting, which guarantee the pump’s working life. Horizontal mount, compact structure, low voice, small vibration, small occupation and stable operation.

Application: Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range: design pressure:1.6Mpa, flow:2-1400m3/h, head:20-125m, power:1.1-110kw

Applicable temperature:-30~120℃, can be up to 350℃ if using new type material.

Optional accessories:monitoring of leakage device, monitoring of temperature device, preventive idling running device.

NOTES: Please indicate during ordering if the proportion of medium is larger than 1.3mg/cm3.No idling running. No delivering medium with particles or crystalline.

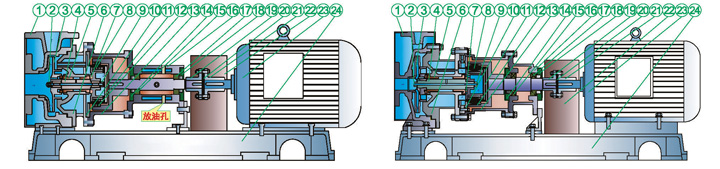

二、Structure drawing

| Part | Material | Part | Material | Part | Material |

| 1.heating type body | 304/316/316L | 9.back nut | 304/316/316L | 17.back bearing | Gcr15 |

| 2.impeller nut | 304/316/316L | 10.gasket | PTFE | 18.back gland of bearing | HT200 |

| 3.impeller | 304/316/316L | 11.distance sleeve | 304/316/316L | 19.pump coupling | 45# |

| 4.pump body | 304/316/316L | 12.outer magnet | permenant magnet/HT200 | 20.diaphragm | 304 |

| 5.shaft sleeve | GRAPHITE/SIC | 13.connecting | HT200 | 21.electric coupling | 45# |

| 6.pump cover | 304/316/316L | 14.front gland of bearing | HT200 | 22.shield | 304 |

| 7.thrust collar | HARD ALLOY | 15.front bearing | Gcr15 | 23.motor | per clients requested |

| 8.inner magnet | permenant magnet/304/316/316L | 16.bearing box | HT200 | 24.base plate | HT200 |

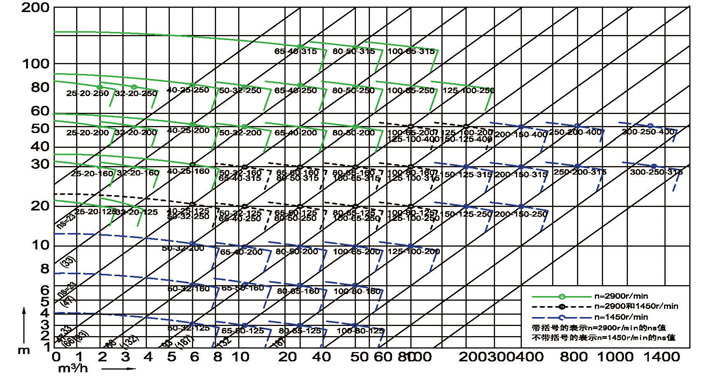

三、Performance Curve:

四、Performance data sheet:

Previous product:TICZ no leakage self-priming magnetic pump

Next Product:TCLF no leakage fluorine lined magnetic pipeline pump